You should have no trouble with the Clough42 ELS conversion. What matters is what is the encoder rpm relative to the spindle rpm and encoder pulses per rev., what is the stepper rpm relative to the gear box input rpm, the gear ratio in the gear box, and the lead screw pitch. These can all be accounted for by adjusting various parameters in the software.

I run my gear box at 1:2 (for higher torque) and my stepper ratio at 1:1. My encoder is running at 1:1 with the spindle and set my lead screw pitch at 24 tpi to account for the gear box ratio.

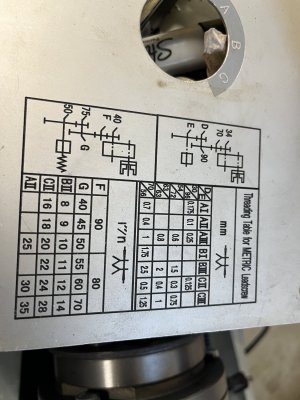

To understand what is happening with your lathe, one needs to know what is going on with the two "black box" rectangles in the diagrams. Uo cut a 12 ti thread with your lead screw, the lead screw need to turn at the same rpm as the spindle. From the Imperial chart. the F and G gears are 80 and 60 respectively. The reduction in rpm by gear train (not including the black box) is 40/80 x 80/60 x 75/50 = 1. If the gear box is et for a 1:1 reduction, then the spindle black box would also be a 1:1 reduction. This is easily verified by counting teeth or measuring the o.d. of the gears of the spindle black box and rotating the lead screw input shaft while observing the lead screw rotation when the selector levers are set in the BII positions.

Since a 127 tooth gear is not used for transposing, other is an approximation being made for either the Imperial or the metric thread. Given that you measured 12 tpi, the 2.1666 mm pitch isn't a nice round number and I would expect the the transposition is from Imperial to metric. Looking at the various metric thread gear combinations, it appears that the metric approximations are not very close at alll so converting to an ELS would be a wise choice.