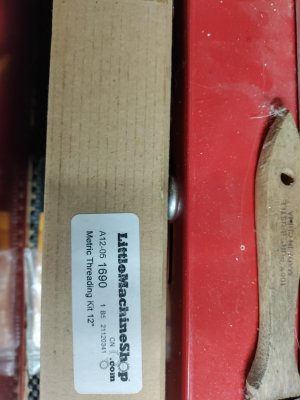

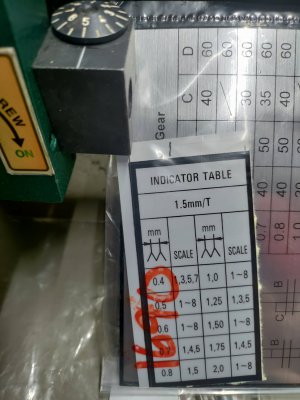

Hi guys. Been a while here. I came across something interesting. I got a 1.5mm pitch leadscrew kit from Littlemachineshop for my grizzly 7x12. It says right on the add that there is no dial, but it came with one. It also came with a chart indicating where you can engage the half nuts for a given pitch. The one thread I did with it worked. I believe it was a 1mm pitch. This flies in the face of conventional wisdom, makes a guy curious. I believe this affects all metric lathes, not just the seig mini flavor. Has anyone tested these all out to see if they work? Do the mini lathes sold elsewhere in the world that come with metric leadscrews also come with this dial? Do other metric lathes have dials? I got in touch with a tech support guy at LMS. He was not aware, but pulled a kit off the shelf and discovered the same dial and chart in it. I would love to have it explained if and why this works.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metric threading dial?

- Thread starter LEEQ

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,097

Generally speaking, metric thread dials come with a number of gears that mesh with the lead screw to accomplish the various metric pitches, I think there were 5 of them supplied with the dial.

- Joined

- Apr 23, 2018

- Messages

- 6,540

Why would the system of measurement matter on a thread dial? The thread dial works on the principle of base frequency and orders of harmonics, they are not relationally coupled to anything but the lead screw pitch. Number base doesn't even matter. All that matters is whether the thread you are cutting is the root frequency or a harmonic thereof. A root thread can be cut on any point of the dial, the first harmonic cuts those options in half, the second harmonic has only 1/4 the positions of the first, and so on.

Mr. York, this dial has no accommodation for change gears. I did notice that not all metric pictures are on that little table they sent. For instance I noticed there was no .75 mm pitch. I think that's a fairly common pitch, however that might not be possible with the number of teeth on the gear in that dial.

Mr Newman, I'm not sure I'm ready to order any harmonicas I'm guessing what you're saying there is if the gear on the dial and the pitch on the screw and the pitch that you are trying to cut share a certain relationship, the dial should work whether it is metric or not. I have seen it brought up that a metric dial would have to have change gears, each change gear representing a range of pitches,but I haven't seen or used one. I am going to try to cut another one or two using this thread dial just to see what happens.

- Joined

- Apr 23, 2018

- Messages

- 6,540

Sorry for that, I see the issue. You shouldn't have to order harmonicas. The (functional) circumference of the gear needs to equal to one linear unit, or a nice round multiple. It would require conversions to go from inch to metric and back. My lead screw is 4 tpi english, where the harmonic concept works throughout the inch range, but when I thread metric, threads may only be started at number 1 on the dial for just that reason. I attest that nothing needs to be changed in order to be useable, but in order to be sensible for the operator, it's easier with the right dial gear.

The metric dial has a 16 tooth gear on the bottom of it that engages with the lead screw. Incidentally it is identical to the gear on the bottom of the dial that came with the lathe (imperial setup). They are both just shy of 9 mm on the OD.