I need to setup for cutting a metric thread and almost pulled the trigger on buying the 37 and 47 tooth gears that people using for metric transposing when you can't fit a 100 and 127 on a smaller machine like my 10" Logan. I started looking for more information about how to set the QCGB using the 37/47 combo and got stuck because most of the resources I could find were for lathes without the QCGB. I did some math and found that maybe the 37/47 combo isn't the best way to go for me. has anyone else run into this?

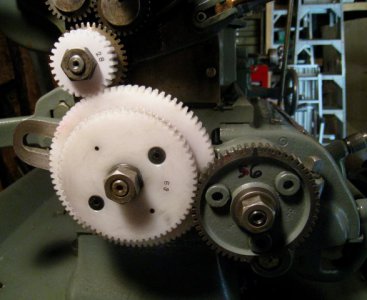

The lathe has a 24t stud gear and a 48t screw gear with a 60t gear to bridge the gap as it is normally. This gives a 2:1 reduction from the spindle to the gearbox and allows for anything from 8TPI to 224TPI. My thinking is to speed up the gear box so that the 8TPI setting effectively becomes a 6mm pitch. I found a few references on PM that seemed to show South Bend did this for their metric setup. In order to speed up the QCGB the only things I would have to change are the stud gear and the screw gear to get a ratio of 0.944882. This can be approximated by a combo of 17/18 or some multiple and accurate to 0.05%. Using this ratio would provide metric pitches of 6, 4, 3, 2, 1.5, 1, 0.75, 0.5, and 0.25.

As anyone else with a QCGB machine tried setting theirs up this way? I'm thinking of using a 51/54 ratio. Maybe there is something I'm missing?

The lathe has a 24t stud gear and a 48t screw gear with a 60t gear to bridge the gap as it is normally. This gives a 2:1 reduction from the spindle to the gearbox and allows for anything from 8TPI to 224TPI. My thinking is to speed up the gear box so that the 8TPI setting effectively becomes a 6mm pitch. I found a few references on PM that seemed to show South Bend did this for their metric setup. In order to speed up the QCGB the only things I would have to change are the stud gear and the screw gear to get a ratio of 0.944882. This can be approximated by a combo of 17/18 or some multiple and accurate to 0.05%. Using this ratio would provide metric pitches of 6, 4, 3, 2, 1.5, 1, 0.75, 0.5, and 0.25.

As anyone else with a QCGB machine tried setting theirs up this way? I'm thinking of using a 51/54 ratio. Maybe there is something I'm missing?