- Joined

- Jul 28, 2017

- Messages

- 2,422

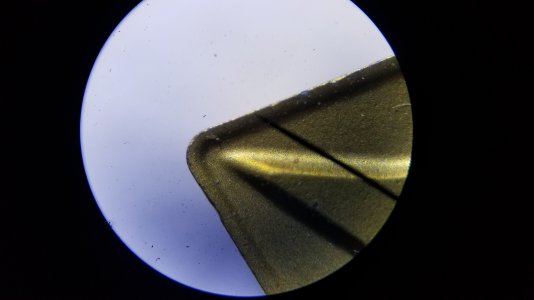

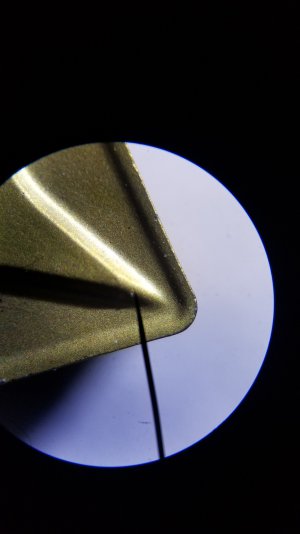

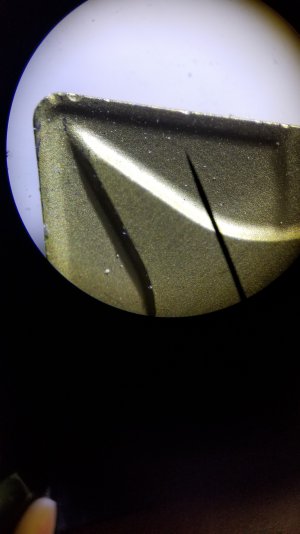

I also got a little USB microscope for cheap. I had been hoping to use it with hand soldering/de-soldering surface mount components, but the slow frame rate drove me nuts. So it's relegated to inspection type jobs. I bought an optical stereo microscope that's much more user friendly for things like circuit board repair. I got it new from Amscope for about $300. That includes the stand, some adapter lenses to get higher or lower magnification and a ring light. It has a trinocular head so you could put a microscope camera on it. I have taken digital photos through an eyepiece but it's kind of fiddly to get everything set up properly -- centered, focused and filling the frame from corner to corner.

So, depending on your needs you may want to check the frame rate on the USB microscopes before you buy.

BTW, the photos of the inserts are really telling. Thanks for sharing them!

So, depending on your needs you may want to check the frame rate on the USB microscopes before you buy.

BTW, the photos of the inserts are really telling. Thanks for sharing them!