- Joined

- Jun 15, 2018

- Messages

- 294

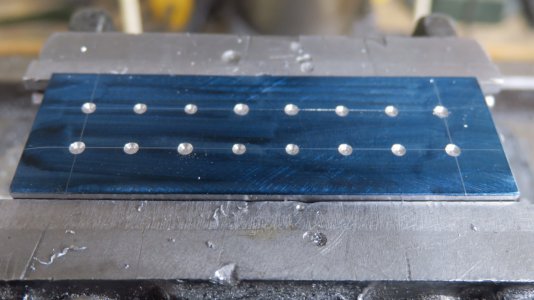

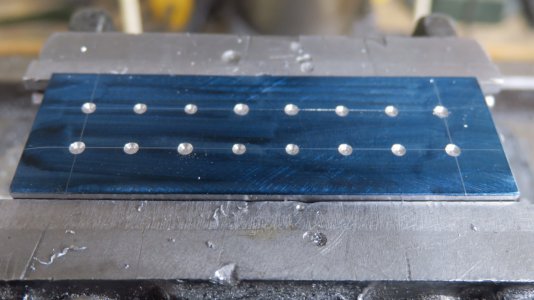

Milling a deep pocket in steel can be an ordeal in a manual machine especially if the steel is tough.

I present a method of making a deep pocket that does not require chip removal by high pressure flood coolant.

In this video I am using:

- Schaublin SV-51 (1955) Milling machine

- Solberga (1975) Drill press

I present a method of making a deep pocket that does not require chip removal by high pressure flood coolant.

In this video I am using:

- Schaublin SV-51 (1955) Milling machine

- Solberga (1975) Drill press

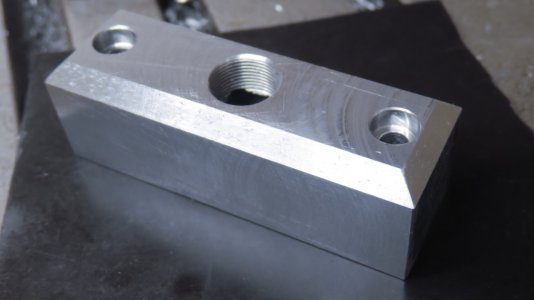

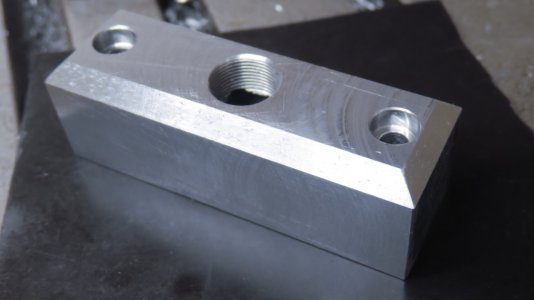

Another thing is that end mills are a lot more expensive than drill bits. So, for the hobbyist, it's far cheaper to hog out with a cheaper (drill) bit and clean up with the more expensive (end mill) bit.

Another thing is that end mills are a lot more expensive than drill bits. So, for the hobbyist, it's far cheaper to hog out with a cheaper (drill) bit and clean up with the more expensive (end mill) bit.