No, it's going to see the most load when it you raise the table. It has to handle the weight of the knee as well as the weight of your vise and work piece. I don't know what the knee is rated for on these mills, it probably won't matter for the typical machining projects, but if you are putting items on there that weigh a lot, it might.Could I reduce the load by locking the elevation screws and then backing off on the gear just a fraction? Kind of like setting the parking brake before shifting into Park?

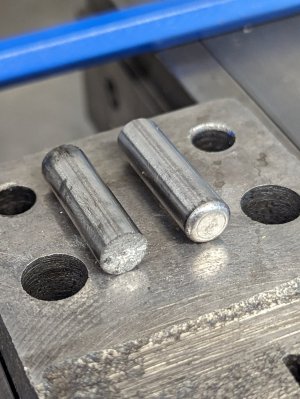

I figured it would be too much luck for them to be exact, but close enough to modify might be good enough.They're definitely easier to find; I just looked them up and found several options. I didn't find measurements yet, but the small gear is an 18-tooth and has a keyed shaft, so I know there's a difference...which makes sense.

That might help, but sounds like a lot of work.I've seen a modification to the knee that addresses this idea: gas struts that push some of the load up and off of the gear set. I'm not sure how I feel about that to be honest, but it's a solid concept...but by the time I buy a pair of gears and then install a set of gas struts, I could have just retrofitted a set of linear actuators to the knee/base and created a power elevator.