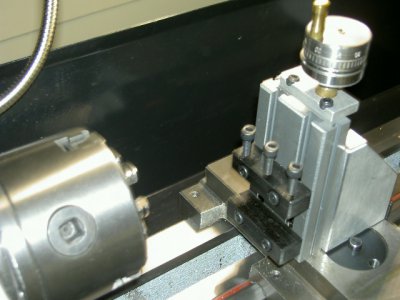

I haven't been able to come up with enough cash to add a mill to my little shop so I picked up an attachment for my lathe cross feed - a vertcal vise with micrometer control - that is marketed to provide milling capability to the lathe. My lathe, MicroLux 7x16, doesn't like this attachment. Regardless of how much rigidity I apply to the lathe structure, end mills jump all over the place and the contact between end mill and material I'm trying to cut is more of a collision than a cutting operation.

Wonder if anyone can offer suggestion(s) on how to make this attachment work as advertised. If you think my naivete got the best of me on this purchase decision don't be shy about saying so. If I made a mistake here I'll just chalk it up to advancing my education on the subject of lathes.

Wonder if anyone can offer suggestion(s) on how to make this attachment work as advertised. If you think my naivete got the best of me on this purchase decision don't be shy about saying so. If I made a mistake here I'll just chalk it up to advancing my education on the subject of lathes.

Last edited: