Hi All,

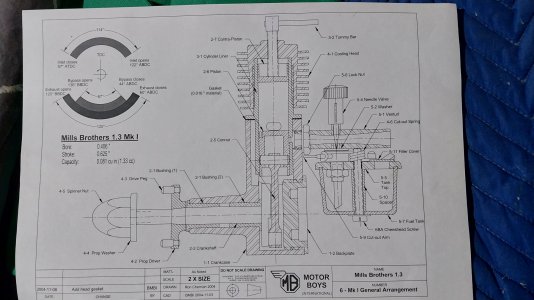

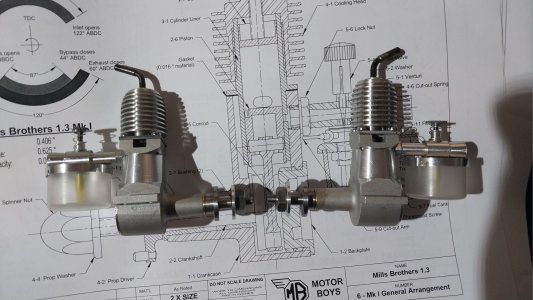

I looked into making a Mills 1.3 engine as they are getting very hard to get.

Found a web site with plans https://outerzone.co.uk/plan_details.asp?ID=13735

Printed the plans out and studied for a few hours. Have found many mistakes in downloaded plans in the past.

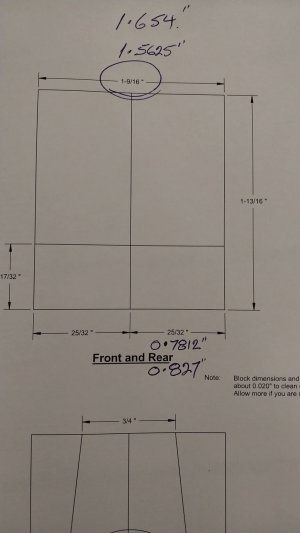

Found a mistake, width of the starter block for the crankcase was marked at 1-9/16" wide. on plans the width of the crankcase is total of 1.654" a difference of 0.0915".

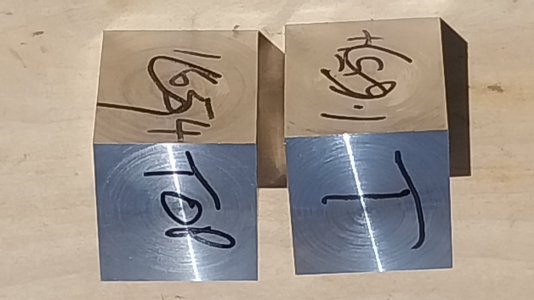

After double checking dimensions, I checked on what I had at hand. I had enough to get started with.

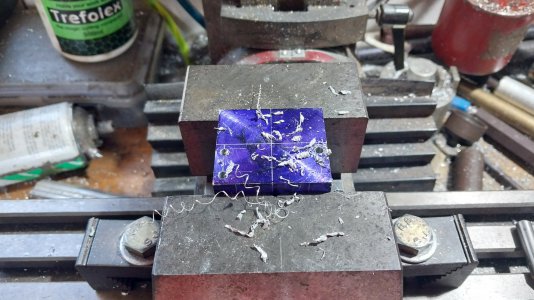

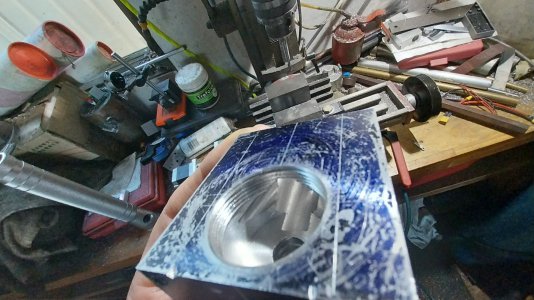

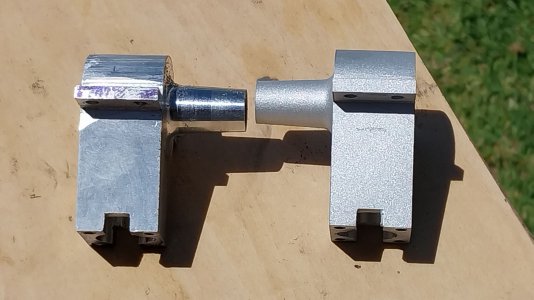

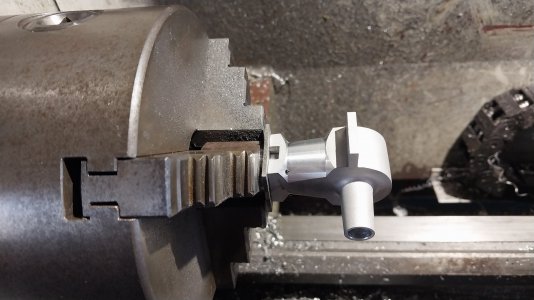

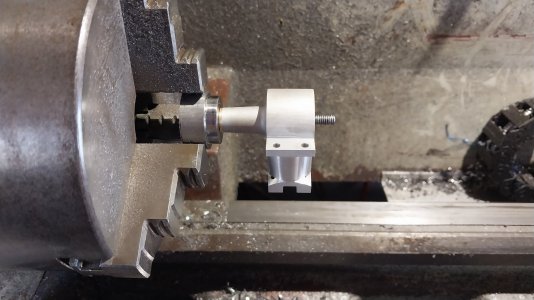

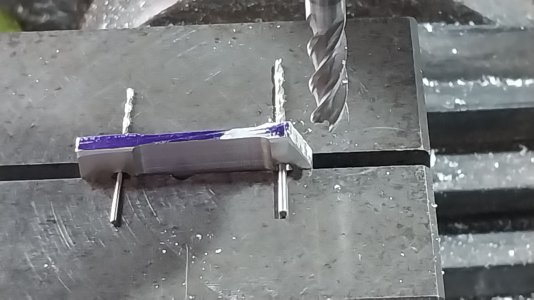

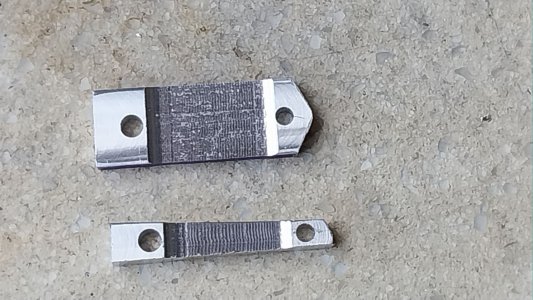

First got the material cut, then squared up and sized the block for crankcase.

Then marked out and drilled 4 holes for the mounting lugs, then drilled and tapped the 4 holes for the cylinder mounting.

Will move on to crankcase machining tomorrow.

Cheers

Andrew

I looked into making a Mills 1.3 engine as they are getting very hard to get.

Found a web site with plans https://outerzone.co.uk/plan_details.asp?ID=13735

Printed the plans out and studied for a few hours. Have found many mistakes in downloaded plans in the past.

Found a mistake, width of the starter block for the crankcase was marked at 1-9/16" wide. on plans the width of the crankcase is total of 1.654" a difference of 0.0915".

After double checking dimensions, I checked on what I had at hand. I had enough to get started with.

First got the material cut, then squared up and sized the block for crankcase.

Then marked out and drilled 4 holes for the mounting lugs, then drilled and tapped the 4 holes for the cylinder mounting.

Will move on to crankcase machining tomorrow.

Cheers

Andrew