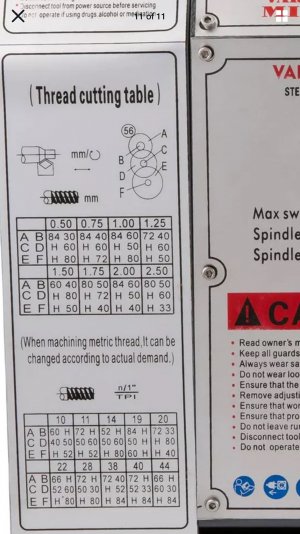

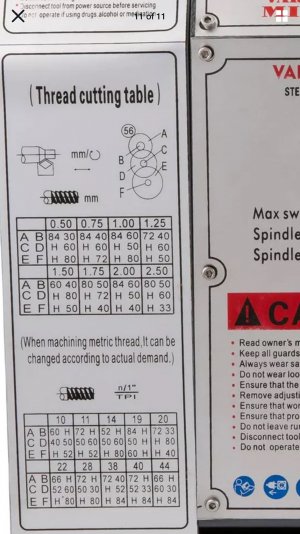

I have a wm210 mini lathe that has the 38mm spindle bore with a 56t gear. The banjo has 3 pairs of gears but the bottom pair is actually a gear and spacer.

The gear calculator on Little Machine Shop produces charts with only 4 gears. Can those gear combinations be used with my setup and if so how?

Here’s a couple of pics of a lathe like mine and metric chart

.

The gear calculator on Little Machine Shop produces charts with only 4 gears. Can those gear combinations be used with my setup and if so how?

Here’s a couple of pics of a lathe like mine and metric chart

.