- Joined

- Jul 28, 2017

- Messages

- 2,555

This project started out as a thought that went from "how hard could it be" to "well I've spent THIS much time on it I may as well finish it".

I found an online description of a clever way to attach a DRO to the cross slide of a mini lathe, which moved the DRO underneath the bed. This got the DRO out of the way better than many other approaches I've seen, so I decided to give it a try. It uses a (backwards) "C" shaped piece that attaches to the back of the carriage, extends vertically to below the bed, and then there's a horizontal section where the DRO is attached. I had a 12" iGaging DRO so I decided to use it for this project.

Unfortunately, I found that the frictional force needed to move the DRO sensor relative to the scale was too great. There's a spring between the scale and DRO body that does two things -- it makes electrical contact to the scale and makes it very "stiff" with regard to external forces. The friction resulted in about a .005" deflection of my C-shaped piece, and that was about the best I could achieve despite efforts to stiffen it up. So I decided to make a replacement body for the sensor, which would use small bearings to perform both functions. My first rendition used 6 flanged bearings, which was convenient because they could constrain the scale on two axes -- but they rubbed too much on the scale. So I ended up using two sets of bearings, four on either side of the scale and four on the top and bottom.

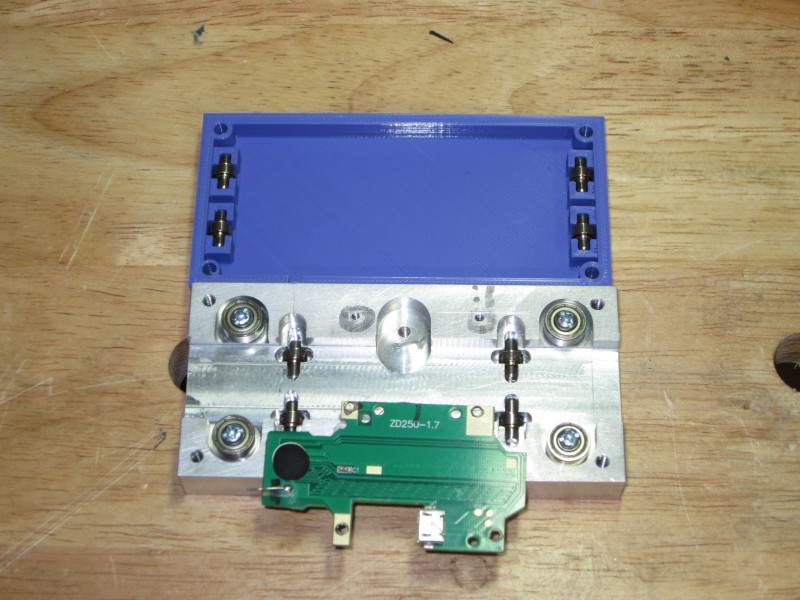

Like this:

The 3D-printed cover goes on top of the aluminum base. It's the first actually-useful item I printed, although I went through about 3 iterations to get it all right. The bearings are 3mm x 6mm, so I used some short 3mm dowel pins for the shafts. The side bearings are mounted using 3mm screws and washers to raise the bearings up so they don't rub on the base.

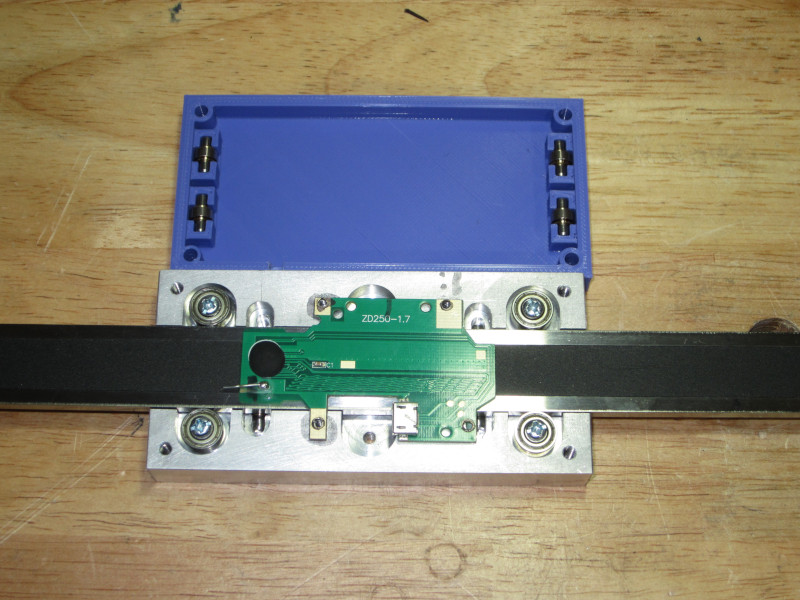

And with the scale and sensor board installed:

The circuit board is the iGaging sensor, removed from the original DRO.

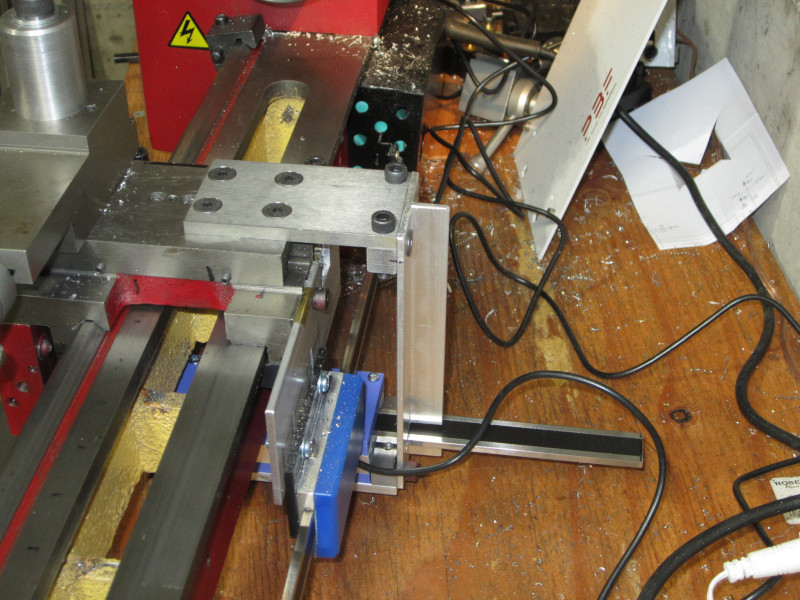

The "C" shaped piece looks like this:

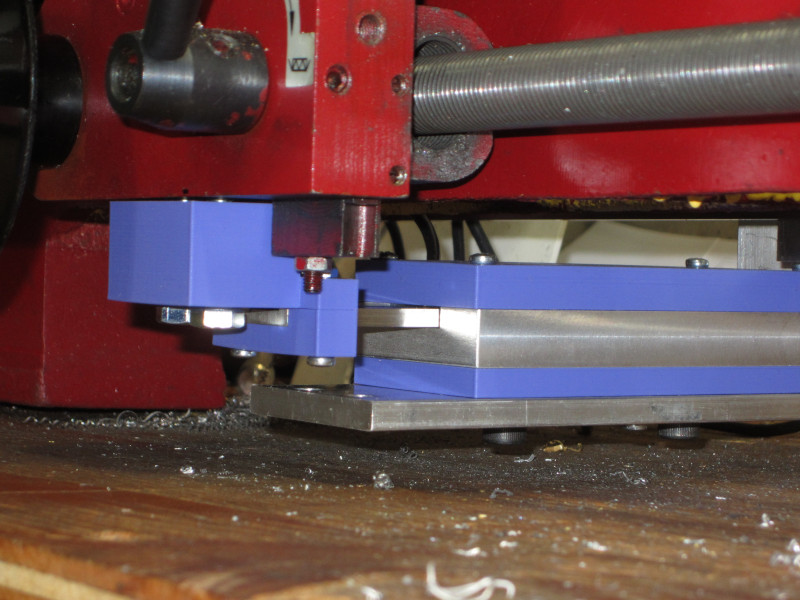

The scale is attached to the apron with two 6mm screws like this:

The 3D printed piece underneath the aluminum body is just a spacer to get the scale to the right height. I also printed a mounting block for the scale.

I had to fiddle around with the spacing between the sensor board and scale. At first the gap was too large so the coupling between the scale and board was too weak, producing a very unstable reading. I replaced the spacer washers with adhesive tape "shims" and now the readout is very stable, even when the motor controller is running. I added a 1uf capacitor between Vcc and Ground on the sensor board, same as what I've done on my mill's iGaging DROs. They greatly reduce the sensor's sensitivity to EMI.

If I had it to do all over again I'm not sure I would. I certainly spent a lot of time getting it working right. I still need to add some kind of swarf guard to keep junk from getting into the DRO. Maybe a soft bristle brush on either end, so the printed cover may see a few more iterations. Sunk cost, yeah.

On the flip side, I gained some design experience making 3D printed items. I used openSCAD, mostly because I found the learning curve to be easier than using a CAD program. The printer is a used Ender 3 I bought from a friend. It seems to produce fairly accurately-sized prints, at least for PLA.

I found an online description of a clever way to attach a DRO to the cross slide of a mini lathe, which moved the DRO underneath the bed. This got the DRO out of the way better than many other approaches I've seen, so I decided to give it a try. It uses a (backwards) "C" shaped piece that attaches to the back of the carriage, extends vertically to below the bed, and then there's a horizontal section where the DRO is attached. I had a 12" iGaging DRO so I decided to use it for this project.

Unfortunately, I found that the frictional force needed to move the DRO sensor relative to the scale was too great. There's a spring between the scale and DRO body that does two things -- it makes electrical contact to the scale and makes it very "stiff" with regard to external forces. The friction resulted in about a .005" deflection of my C-shaped piece, and that was about the best I could achieve despite efforts to stiffen it up. So I decided to make a replacement body for the sensor, which would use small bearings to perform both functions. My first rendition used 6 flanged bearings, which was convenient because they could constrain the scale on two axes -- but they rubbed too much on the scale. So I ended up using two sets of bearings, four on either side of the scale and four on the top and bottom.

Like this:

The 3D-printed cover goes on top of the aluminum base. It's the first actually-useful item I printed, although I went through about 3 iterations to get it all right. The bearings are 3mm x 6mm, so I used some short 3mm dowel pins for the shafts. The side bearings are mounted using 3mm screws and washers to raise the bearings up so they don't rub on the base.

And with the scale and sensor board installed:

The circuit board is the iGaging sensor, removed from the original DRO.

The "C" shaped piece looks like this:

The scale is attached to the apron with two 6mm screws like this:

The 3D printed piece underneath the aluminum body is just a spacer to get the scale to the right height. I also printed a mounting block for the scale.

I had to fiddle around with the spacing between the sensor board and scale. At first the gap was too large so the coupling between the scale and board was too weak, producing a very unstable reading. I replaced the spacer washers with adhesive tape "shims" and now the readout is very stable, even when the motor controller is running. I added a 1uf capacitor between Vcc and Ground on the sensor board, same as what I've done on my mill's iGaging DROs. They greatly reduce the sensor's sensitivity to EMI.

If I had it to do all over again I'm not sure I would. I certainly spent a lot of time getting it working right. I still need to add some kind of swarf guard to keep junk from getting into the DRO. Maybe a soft bristle brush on either end, so the printed cover may see a few more iterations. Sunk cost, yeah.

On the flip side, I gained some design experience making 3D printed items. I used openSCAD, mostly because I found the learning curve to be easier than using a CAD program. The printer is a used Ender 3 I bought from a friend. It seems to produce fairly accurately-sized prints, at least for PLA.