- Joined

- May 17, 2016

- Messages

- 3

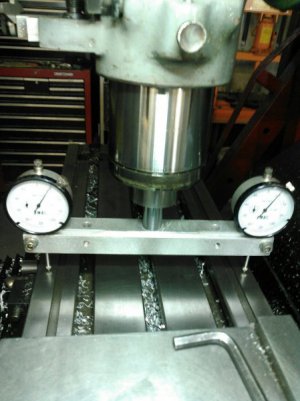

Hi everybody. I apologize in advance if this is not the best place to post this question. I have looked around a bit but I'm new here and still getting the hang of the forum. I have a HF Mini Mill and I'm trying to learn the basics. I'm having trouble tramming and was wondering if anybody can give me any tips based on the tools I am using.

Harbor Freight Mini Mill

Interstate 4" mill vise

Cheap Dial test indicator from LMS

Cheap clamping holder, unknown brand

I know cheap is not the way to go but I'm trying to work with what i can afford right now. I've read up and watched some youtube videos about how to tram the mill and I'm just having trouble getting things level. I will be using the vise for most projects so I figure it is best to tram using that surface. Just to get started, I thought I would check along the top edge of the vise jaws, although it doesn't seem like that is a relevant surface to measure against. Anyway, it seems that no matter how hard I try, I just can't get things level. The indicator also seems to jump around quite a bit which makes me think I should be using the indicator at more of an angle rather than somewhat vertical like I have been. Maybe this causes it to "skid" around on the vise surface? I would appreciate any tips or advice from anybody who might be able to shed some light on how I can successfully tram this mill. Feel free to tell me I'm doing everything wrong because I most likely am. Glad to be here!

Harbor Freight Mini Mill

Interstate 4" mill vise

Cheap Dial test indicator from LMS

Cheap clamping holder, unknown brand

I know cheap is not the way to go but I'm trying to work with what i can afford right now. I've read up and watched some youtube videos about how to tram the mill and I'm just having trouble getting things level. I will be using the vise for most projects so I figure it is best to tram using that surface. Just to get started, I thought I would check along the top edge of the vise jaws, although it doesn't seem like that is a relevant surface to measure against. Anyway, it seems that no matter how hard I try, I just can't get things level. The indicator also seems to jump around quite a bit which makes me think I should be using the indicator at more of an angle rather than somewhat vertical like I have been. Maybe this causes it to "skid" around on the vise surface? I would appreciate any tips or advice from anybody who might be able to shed some light on how I can successfully tram this mill. Feel free to tell me I'm doing everything wrong because I most likely am. Glad to be here!