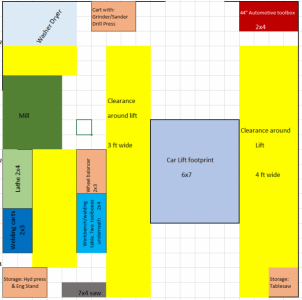

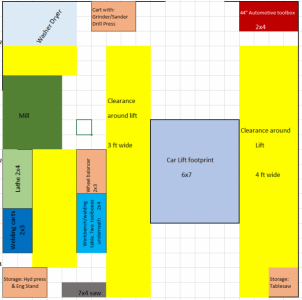

So I'm trying to better organize my 2 car garage where one bay is dedicated to automotive work (with a lift on that side). The second half (approx 16ft x 7.5ft) has to accomodate my lathe and mill, as well as other garage tools, welders etc. Is 3ft isle size wide enough to work in front of a lathe or a mill? Any other thoughts as to the layout?

The welding/work bench will be flat top so I can access it from either side of it (from the yellow isles).

The welding/work bench will be flat top so I can access it from either side of it (from the yellow isles).

Last edited: