- Joined

- Nov 27, 2012

- Messages

- 7,854

Another loooong overdue project. The Mitu scale has been sitting around for way too long, I got it from Enco during a sale, that's how long it's been.

Warning: There's a lot of photos in this post!

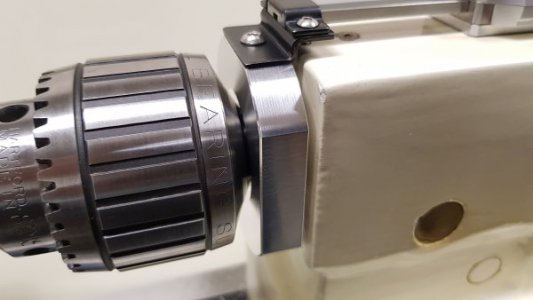

My tailstock has 4" of travel. To maximize the use of travel for drilling, I shortened my arbors so they eject when the quill is close to fully retracted. With full length arbors I loose quite a bit of travel. I made my bracket to mount on the quill using set screws so it doesn't affect any loss in the travel I had before.

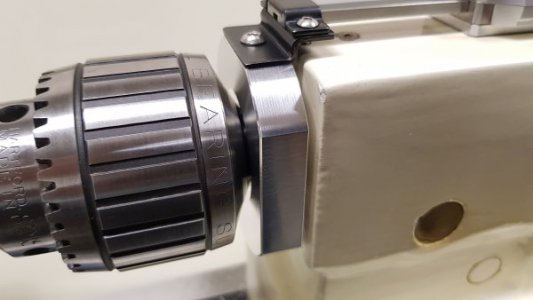

I use the Bison keyless chuck pictured above most of the time. My Jacobs 14N sits a lil bit closer than the Bison chuck before it ejects. Although I didn't need to, I matched the taper of the 14N on the face of the bracket to give me more clearance for the future if I ever need to ream the TS quill.

This is how much room I have before my drill chucks eject.

Bracket mounts on the quill with exactly half it's thickness, sits right at the 0 mark but not that it really matters.

The following are WIP pics if interested.

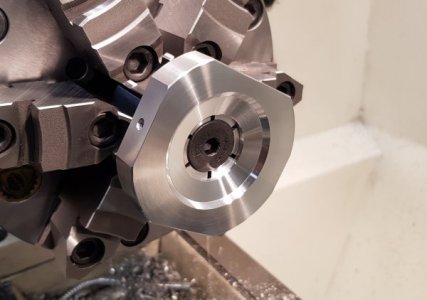

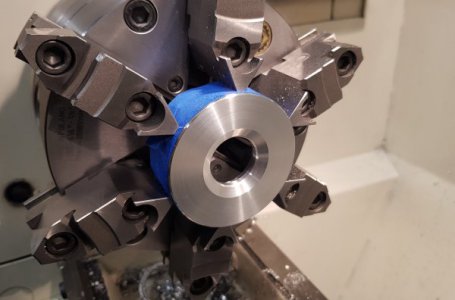

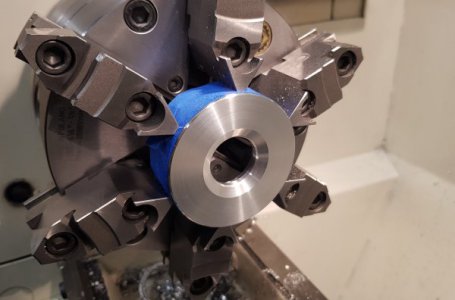

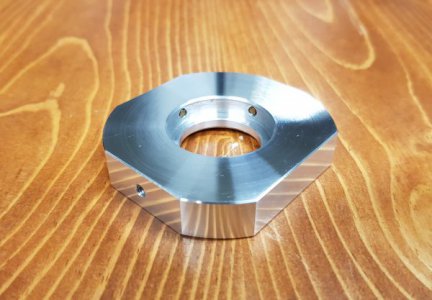

Making the bracket.

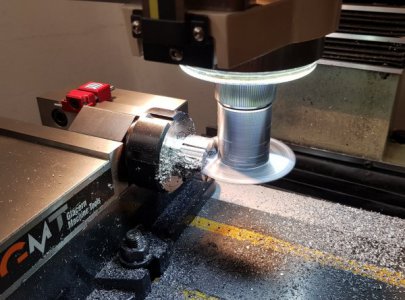

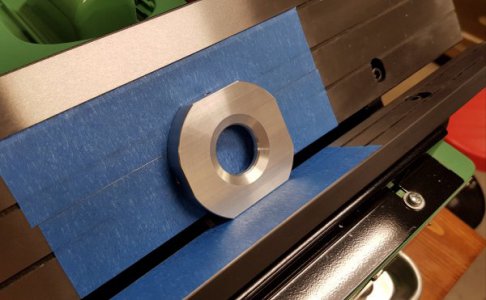

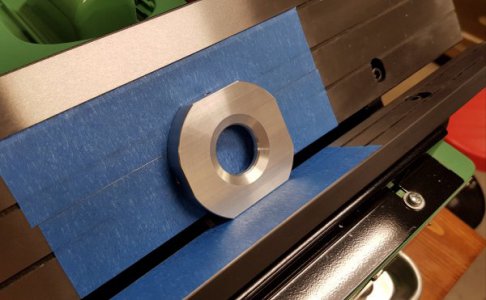

Used my "cheater" machine to chamfer the flats to match the chamfer on the radius done on the lathe.

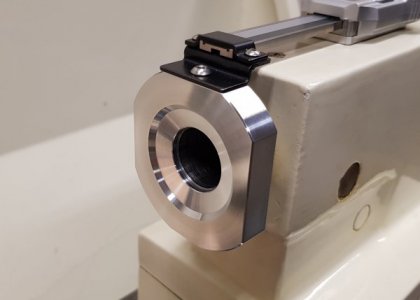

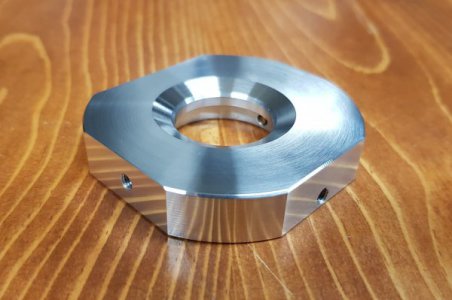

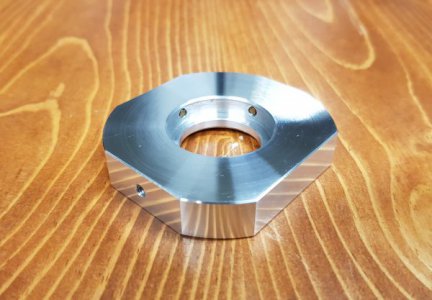

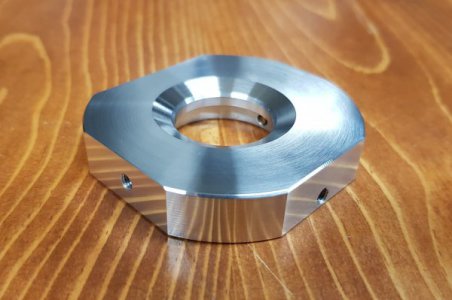

Finished bracket. I'm using brass tipped set screws.

Made a spacer for the read head. Yes, I am using double sided tape to mount it. I've found Duck brand carpet tape is really strong stuff. Not critical here anyway but it's strong enough to give good measurements. I've actually got my mill quill DRO mounted with the same stuff & it has been holding up great for many yrs now.

Before I could mount it all up, I first had to address the rotational slop for the quill. The slop has always bothered me but it didn't affect anything so I never got around to fixing it. Now I needed to. Made a new key to take care of that.

And finally, shortened the scale to appropiate length.

Thanks for looking if you made it this far!

Warning: There's a lot of photos in this post!

My tailstock has 4" of travel. To maximize the use of travel for drilling, I shortened my arbors so they eject when the quill is close to fully retracted. With full length arbors I loose quite a bit of travel. I made my bracket to mount on the quill using set screws so it doesn't affect any loss in the travel I had before.

I use the Bison keyless chuck pictured above most of the time. My Jacobs 14N sits a lil bit closer than the Bison chuck before it ejects. Although I didn't need to, I matched the taper of the 14N on the face of the bracket to give me more clearance for the future if I ever need to ream the TS quill.

This is how much room I have before my drill chucks eject.

Bracket mounts on the quill with exactly half it's thickness, sits right at the 0 mark but not that it really matters.

The following are WIP pics if interested.

Making the bracket.

Used my "cheater" machine to chamfer the flats to match the chamfer on the radius done on the lathe.

Finished bracket. I'm using brass tipped set screws.

Made a spacer for the read head. Yes, I am using double sided tape to mount it. I've found Duck brand carpet tape is really strong stuff. Not critical here anyway but it's strong enough to give good measurements. I've actually got my mill quill DRO mounted with the same stuff & it has been holding up great for many yrs now.

Before I could mount it all up, I first had to address the rotational slop for the quill. The slop has always bothered me but it didn't affect anything so I never got around to fixing it. Now I needed to. Made a new key to take care of that.

And finally, shortened the scale to appropiate length.

Thanks for looking if you made it this far!