- Joined

- Oct 12, 2023

- Messages

- 40

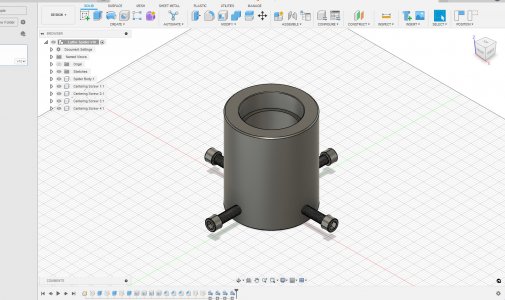

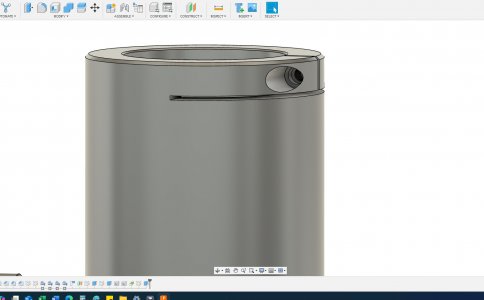

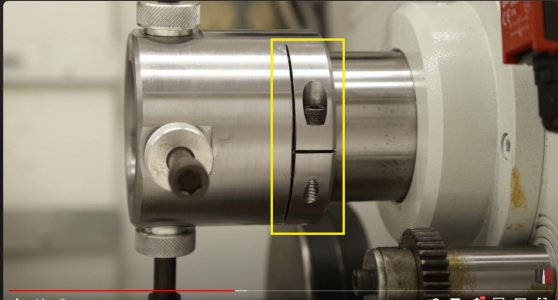

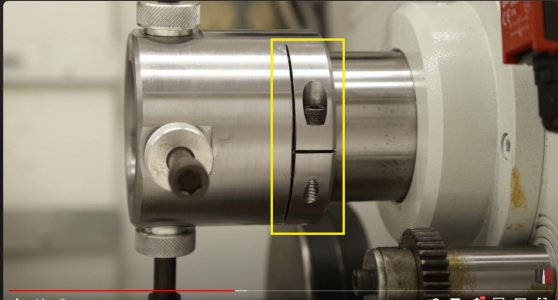

So I am working on modeling a lathe spider, both for practice with CAD and to make drawings to take down to the shop so I'm not just winging it as I go. I am new to the software, and have just been googling what I am trying to accomplish and following the tutorials on YouTube. But I'm not having much luck for this step. Any suggestions on where to start would be awesome. Pics included for clarity. Also, I'm thinking it would be better to model the threaded hole and counterbore before the slit. Would you all agree?

What I have so far

What I have so far