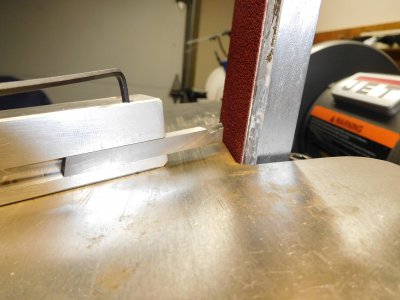

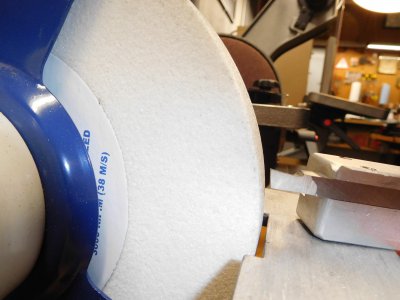

I bought the Jet sander after reading all the accolades given to grinding tool bits on belt sanders. I had never tried it before, so I thought it just might be time. I have only used bench grinders previously. Now I find that I can remove metal faster and with good angle control using the belt sander. It works great with the glass platen that I made for it. However, I think that I will still use my bench grinder for fine tuning and touch up. It is a slow speed with fine grit wheels (rikon 8" 1800 rpm from Woodcraft)

I have two small lathes, a Sherline and a Taig. And I have Boley and Levin watchmakers lathes. So I primarily use 1/4, 3/16, and 1/8" HSS tool bits. I have insert tooling for the Sherline and Taig, but prefer the HSS bits for most work.

As a side note, I have experimented with the "shear" style tool bit and find that it does work as advertised. Easy to grind and produces a very nice finish on carbon steel.

Thanks to all the posts with all the great information on tool grinding. I have improved my technique and reduced the grinding time.