- Joined

- Dec 18, 2019

- Messages

- 6,447

Thanks for that. Guess I need to figure out how to make a clamp for the die grinder/dremel. I need to hold one item, not two... I find that holding the grinder is awkward and I'm always worried about wheel breakage and getting smacked in the face. I wear safety glasses, but, still when stuff breaks, stuff goes flying in an unpredictable fashion.My first thought for odd tool shapes is a die grinder/dremmel. I think I'd try to get the bulk of the material off with the belt grinder, then switch to the smaller tool. Probably hold on to the tool in a vise and cool with a squeeze bottle of water. I'm not sure what to suggest for grinding media though.

One alternative I have seen done on a Joe Pie video, cut in the mill with carbide tooling. It's probably tough on tooling, but it did work.

I'm interested in seeing what others suggest. I haven't made too many specialized tools.

In the past I used a dremel and diamond files. The experience was slow, slow, slow and tedious. It was awkward using the dremel and the removal rate wasn't that quick. In the end, it did work, but took days of effort to finish the tool bit. Consequently, I have avoided doing it much.

Revisiting this, to find a way that is faster and hopefully a bit easier.

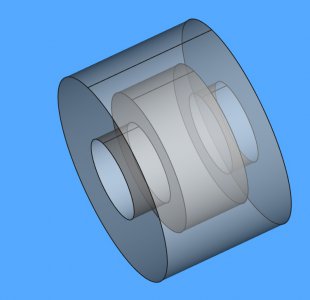

Trying to make something like this: