I agree with you. I find myself jumping from page 27 to pages 4 and 5 constantly while grinding these tools. I think most people will read the first page hoping to find the information and not want to go through 27 pages to find the answers but then again there’s a lot more information in here then just on grinding the specific tools. Just so you know and everyone else knows, the majority of information you’re looking for is on page 4 and 5.

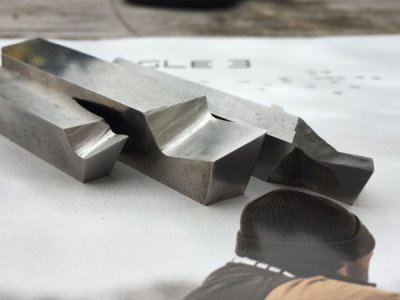

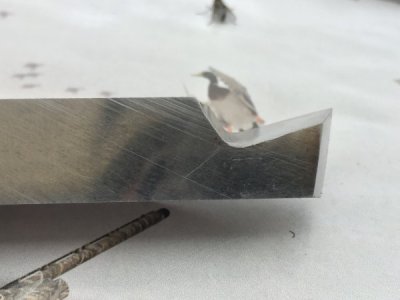

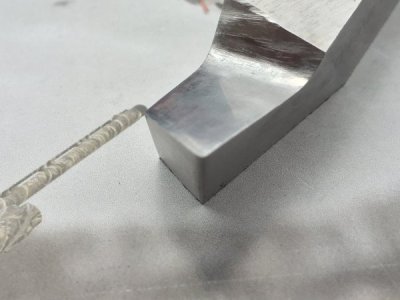

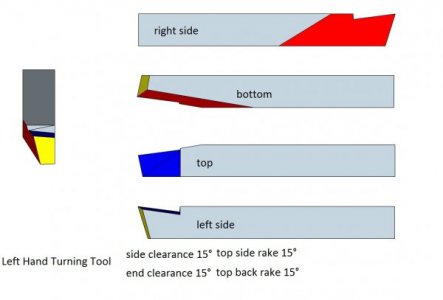

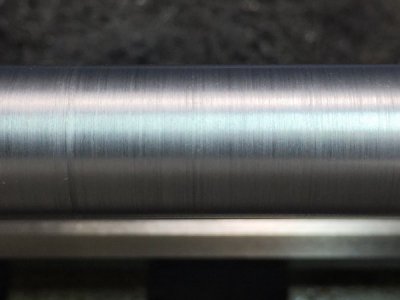

This thread is really great. The only problem is that it has become so large that it is unwieldy to use and hard to find stuff. One thing that I would find to be very usable is if there could be one place on the forum where the basic information in this thread could be presented. I am thinking of drawings, not pictures, of the different types of tool bits with the angles for the tool. My lathe came with a chart to be mounted on the wall for quick reference for the basic tool bits. It really helped me with grinding tool bits. I couldn't scan the entire chart do to it's size. A portion of the chart is attached.

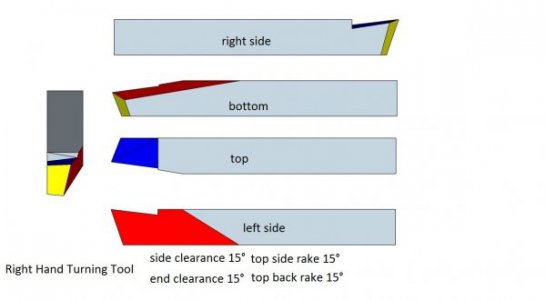

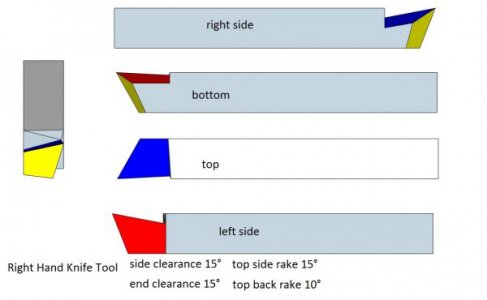

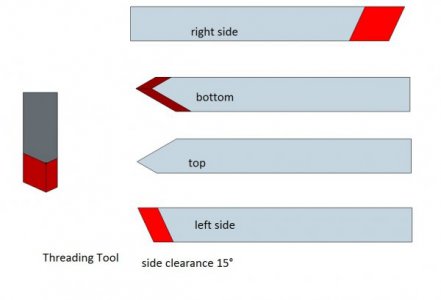

I would be willing to do the drawings. I use google sketchup for drawing. Sketchup drawings are 3D that I would then convert into a jpg showing top, bottom, side and front views that could be uploaded to the forum.

No forum that I have been on allows sketchup drawings to be uploaded. If the actual sketchup drawing could be uploaded then the drawing could be viewed in sketchup where you could rotate and spin the drawing to whatever angle you wanted for viewing. Sketchup is a free program.

Just a suggestion.