-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jan 4, 2021

- Messages

- 912

I was curious myself, so I did a little googling. What I found suggests this formula tells you:

Number of poles in an induction motor can be found by the following formula

P=(120*f)/N

where f = frequency of the rotating field .

N = the speed at which the motor is running

Looks like this is a 2 pole motor, if that information is correct. I also read that the more poles, the slower the motor will run.

Number of poles in an induction motor can be found by the following formula

P=(120*f)/N

where f = frequency of the rotating field .

N = the speed at which the motor is running

Looks like this is a 2 pole motor, if that information is correct. I also read that the more poles, the slower the motor will run.

- Joined

- Apr 30, 2015

- Messages

- 11,329

The number of coils is different from the number of poles, something I'm still trying to get my head around

- Joined

- Dec 14, 2018

- Messages

- 629

I wound coils and stuffed them several years ago when the winding dept was over busy and shorthanded. The way the coils were wound in groups and connected determined the number of poles (I believe). I never got too technical because my main job was machinist.

- Joined

- Feb 13, 2017

- Messages

- 2,138

Induction motor speeds are related to frequency. A 2 pole motor, which yours is, runs at 3600 RPM, less a little for "slip". A 4 pole motor runs at 1800, again less a little. 2 pole motors have a working speed around 3450 RPM. 4 pole motors have a working speed around 1750 RPM. The actual speed will vary from motor to motor, but is always in tat range. Countries that use 50 Hz will be slower, at 3000 and 1500 respectively. Motor speed is actually a factor of frequency, less slip. Slip gets into serious motor theory so I won't go into it here. It's several chapters deep. . .

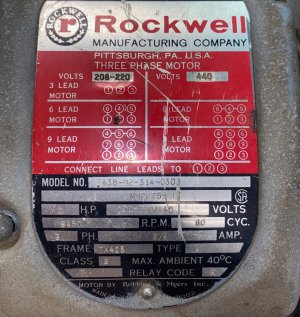

Basically, for a US motor that runs on 60 HZ, the "synchronous" speed will be determined by the formula F=PS/120. F is frequency, here 60 Hz. P is poles and S is speed in RPM. So speed is directly related to poles. Your motor is a "3 phase, 9 wire" motor. In that it is either 240 or 480 volts, depending on connections.

I looked at your nameplate for speed, 3600- is a two pole. Simple as that. . .

.

Basically, for a US motor that runs on 60 HZ, the "synchronous" speed will be determined by the formula F=PS/120. F is frequency, here 60 Hz. P is poles and S is speed in RPM. So speed is directly related to poles. Your motor is a "3 phase, 9 wire" motor. In that it is either 240 or 480 volts, depending on connections.

I looked at your nameplate for speed, 3600- is a two pole. Simple as that. . .

.

- Joined

- Apr 30, 2015

- Messages

- 11,329

I've noticed the slip speed is often listed on the dataplate- I.E. 3450 for a 3600, 1725 for 1800 etc.

- Joined

- Feb 13, 2017

- Messages

- 2,138

That's because the "slip" speed is the actual running RPM under a nominal load. Synchronous speed only applies to to true synchronous motors. Synchronous motors are usually, at least on larger industrial motors, started as induction motors. There are several methods, depending on just how big a motor is involved. When they have reached "slip" speed, the field is excited and they "lock in" to synchronous speed. The ones I worked on were 900 HP and around 12-14 feet in diameter and a couple of feet between bearing caps.I've noticed the slip speed is often listed on the dataplate- I.E. 3450 for a 3600, 1725 for 1800 etc.

Using synchronous speed for induction motors is a "ranging" number used to determine the number of poles. Just like line voltage that can vary from 208 to 240 volts, depending on, usually, age and wiring of a substation, synchronous speed is determined by the formula "F=PS/120" minus the slip. As an example, when I speak of an 1800 RPM motor (synchronous speed), it is a four pole motor. The few RPM lost through slip doesn't matter. There are 2, 4, 6, 8, etc pole motors, for each pair of poles there is a speed range connected to it. In the States, frequency is assumed to be 60 Hz. In much of the rest of the world, it is 50 Hz. Beyond motors running slower, 1500 RPM vs 1800 RPM, there are some lesser issues that really don't affect the end result that much.

Where, as stated above, motor windings rate several chapters in the theory books, synchronous motors rate entire books. The simplified version is to use the stated speed from the name plate and round it up to the next even number divisable by 60 (or by 50 for non US motors) to get synchronous speed, from which can be determined the number of poles. The information presented here would take a week in today's technical schools. There I go again, waxing political. I'm outta here. . .

.

Last edited:

. . .

. The ones I worked on were 900 HP and around 12-14 feet in diameter and a couple of feet between bearing caps.

I wondered how electric vehicle makes motor with high horse power rating. Do they use high voltage or something like that to solve the size issue? It would be nice to use the same technology for everything else.