I had posted earlier, in the dedicated Atlas section, about specific issues with an Atlas horizontal mill I had just acquired. This seems a more generic question with wider application.

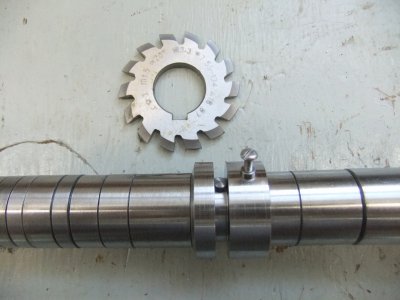

The arbor for the mill is 7/8" dia with a single keyway. While I have several cutters/slitting saws few of them have the same width of keyway. For my initial trials I have held them in place by the friction generated between the spacers & the arbor shaft nut (outboard of all the spacers. So far it has worked... but... is there a danger of slippage? More precisely, of course there is always a possibility but how likely is it to occur given the machine's capabilities?

Selecting only cutters with the correct size keyway would severely limit my choices. I do have a source of brand name, lightly used cutters but there are only a few cutters with the correctly sized keyway.

If this is a screw-up waiting to happen what alternate solutions are there?

I considered the idea of a key milled to the width/depth of the arbor keyway on one side & to the width/depth of the cutter on the other (would resemble a T-nut minus the threaded hole for a stud)? Is this a practical/realistic approach?

Another idea: purchase cutters with larger diameter openings for the milling machine arbor and then fabricate

a spacer ring with dual keyways: the spacer's internal keyway would be sized to fit the arbor's and the outside keyway would accept a key suitable to that of the cuter. This sounds - maybe - like a lot of work for questionable results.

The arbor for the mill is 7/8" dia with a single keyway. While I have several cutters/slitting saws few of them have the same width of keyway. For my initial trials I have held them in place by the friction generated between the spacers & the arbor shaft nut (outboard of all the spacers. So far it has worked... but... is there a danger of slippage? More precisely, of course there is always a possibility but how likely is it to occur given the machine's capabilities?

Selecting only cutters with the correct size keyway would severely limit my choices. I do have a source of brand name, lightly used cutters but there are only a few cutters with the correctly sized keyway.

If this is a screw-up waiting to happen what alternate solutions are there?

I considered the idea of a key milled to the width/depth of the arbor keyway on one side & to the width/depth of the cutter on the other (would resemble a T-nut minus the threaded hole for a stud)? Is this a practical/realistic approach?

Another idea: purchase cutters with larger diameter openings for the milling machine arbor and then fabricate

a spacer ring with dual keyways: the spacer's internal keyway would be sized to fit the arbor's and the outside keyway would accept a key suitable to that of the cuter. This sounds - maybe - like a lot of work for questionable results.