- Joined

- Dec 3, 2017

- Messages

- 1,909

Way to go! See, it seems these guys forgot the Cardinal rule of HSM. Which I always thought was “celebrate every posted purchase with hardy approbation and lavish praise.”

I for one, am stoked that you have bought something you wanted, and excited to find out what you learn with it.

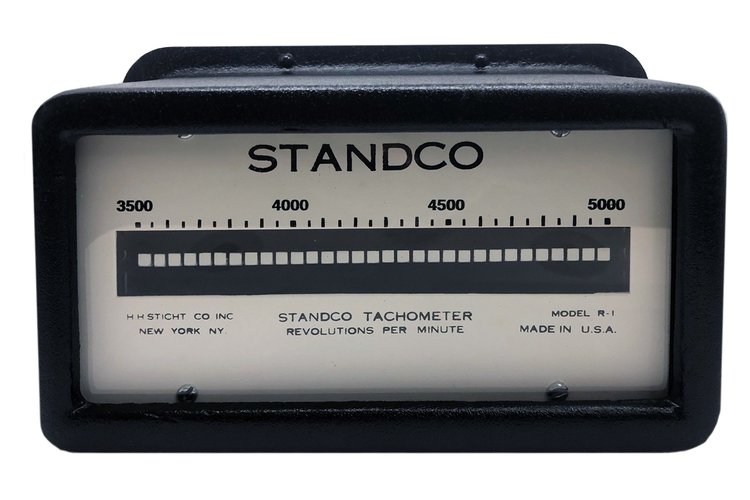

Now if’n I wanted to have a permanent mechanical rpm readout, I might scavenge something from the pick a part car yard. But it’s been very seldom I thought knowing the precise rpm would help me. There’s a lot I don’t know though. Maybe your experiment will make me a convert.

I for one, am stoked that you have bought something you wanted, and excited to find out what you learn with it.

Now if’n I wanted to have a permanent mechanical rpm readout, I might scavenge something from the pick a part car yard. But it’s been very seldom I thought knowing the precise rpm would help me. There’s a lot I don’t know though. Maybe your experiment will make me a convert.