- Joined

- Aug 7, 2022

- Messages

- 1

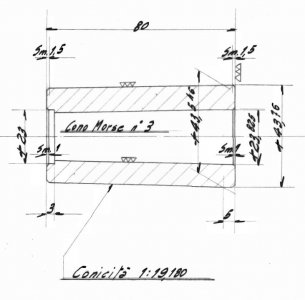

I know this is an old post but I have an old 1920s sunstrand 14 inch lathe. I couldn't figure out which taper it had after but after some research I concluded that the only thing it could be due to the measurents was a morse taper 4.5. I noticed that the specs in terms of taper angle was almost the same as Mt 4. I searched the internet and couldn't even find a Mt 4.5 dead center. I just said to he'll with it, I put my mt4 dead center between centers and indicated it in with my taper attachment. After cutting the taper and cleaning the spindle bore up with a little fine grit it fit perfect. I even get that nice satisfying thunk when I seat the taper in the spindle. After wiping the ear to ear grin off my face I went ahead and turned a drawbar and nut. So I guess you could say that if you have an mt4 dead center. It's close enough to and Mt 4.5 it will work if you want to make your own stuff. Maybe I'll make that er 40 collet chuck nextYep...even my 1970’s era American made Clausing is a MT 4.5

I said the same thing. Oh my gosh. How can that be. Anyway, once past the shock of a Morse Taper in halves, I found a used adapter to go from MT 4.5 to MT 3 on EBay

not sure I’d really invest in that again even though I don’t regret buying it. I say that because when I want to turn between centers... I usually just stick a round chunk of steel in my 3 jaw chuck and turn a 60 degree point on it and that’s my dead center. It’s easier than removing my chuck.