- Joined

- Oct 13, 2014

- Messages

- 6,703

Hi markba633csi,

Thanks for your response, I see you like BMW coupes

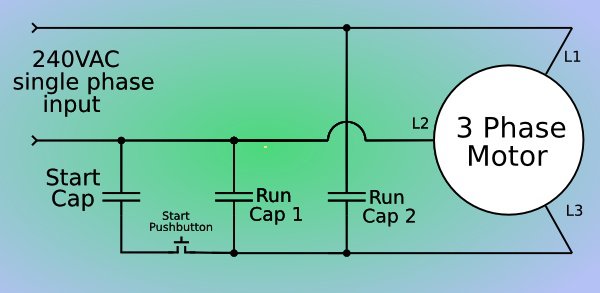

My third paragraph is talking about how the RPC works within the YouTube video that I posted where the design gives 2 ghost legs when the Idle motor is running and only uses the Neutral within the circuit upon startup. This setup keeps the Neutral where it should be at the Star point, in the USA you do not need to use this method mainly because you already have your Live split into 2 at the consumer board within a domestic supply. These 2 Lives spin the motor without needing to use the Neutral (albeit they are both under powered compared to a real 3 phase supply)

To clarify something: The "legs" L1, L2 we get here in the states are technically not "phases"(though they are usually referred to as), they are a single phase split into 2 "legs". Thats why it's called "single phase even though there are 2 "hot legs". So here at the utility pole a single 240V phase (just like you have) is split into the two 120V legs, 180 degrees apart. When one leg is at +120V the other is at -120V acting as the return path thus the potential between the two is 240V. A 240V to neutral will give the same potential. So a single phase 240V motor will work either with 2 120V legs attached or a 240V phase and a neutral, to the motor it's the same. The phase is split here because we use 120V for lighting and small appliances. Europe et, al. don't use 120V so no need to split it.