- Joined

- Jul 11, 2014

- Messages

- 496

:newspaper:I read an article in the June/July 2012*Vol. 25. No. 3 issue of 'Machinist WorkShop' on modifying a 5C Spin-Indexer. "Hey!" thinks I, "What a great idea, I'll do that to mine and make it more versatile." It seemed like a simple straight forward project for my type of shop. Since the article gave metric dimensions my first task was conversion of the dimensions to inches. The standard conversion divisor of 25.4 solved that in no time. Then it was make a few sketches & out to the shop to begin. It was all just simple straight forward machining. Saw, part-off, drill & tap, face & turn. nothing elaborate.:cool2:

It seemed like a simple straight forward project for my type of shop. Since the article gave metric dimensions my first task was conversion of the dimensions to inches. The standard conversion divisor of 25.4 solved that in no time. Then it was make a few sketches & out to the shop to begin. It was all just simple straight forward machining. Saw, part-off, drill & tap, face & turn. nothing elaborate.:cool2:

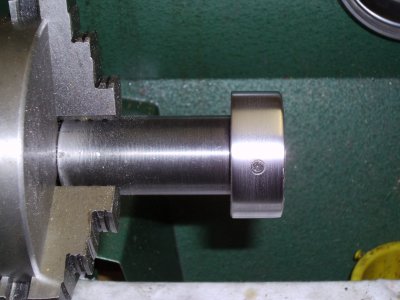

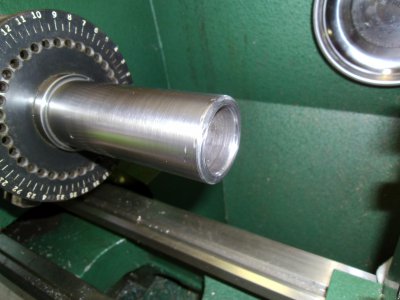

I got busy dismantling the indexer and began. At first all went well, I sawed off the tube, faced it and then cut the crank handle off the end and turned it down just enough to clean the surface of paint etc. It was mild steel and cast iron so no big deal. Then I ran into a snag, I had assumed (O don't do that) ({:- headache: the spindle was mild steel also since this was not a high-end indexer and the guy in his article said both his tube and spindle were machinable and could be cut on his power saw. Great! Not!

headache: the spindle was mild steel also since this was not a high-end indexer and the guy in his article said both his tube and spindle were machinable and could be cut on his power saw. Great! Not!

I found out real fast it was hardened and ground. Should've checked first, I know, I know, as usual I jumped in with both feet without checking the depth of the water. I could cut it with great difficulty using a carbide and taking no more than .010 at a pass. That was tedious and I wasn't sure if my patience or carbide inserts would wear out first. What to do?:bitingnails: anic:

anic:

Ah-ha! I thinks, I have a friend who has a 'chop' saw (Abrasive cut off saw) I will approach today and see if it will handle this spindle. Should cut through it and anneal the end somewhat to make it more amenable to machining. (Hear I go again assuming) I don't know if his saw will handle this, if he'll want to let me do this with his saw or if he's even going to be home today.

So this project is on hold for the time being, whether that be long or short. But as I solve this problem and move on I'll post some photos (yes I've been taking them) of how things went.

So far it's a mild 'FUBAR' defrugaltie..

I got busy dismantling the indexer and began. At first all went well, I sawed off the tube, faced it and then cut the crank handle off the end and turned it down just enough to clean the surface of paint etc. It was mild steel and cast iron so no big deal. Then I ran into a snag, I had assumed (O don't do that) ({:-

I found out real fast it was hardened and ground. Should've checked first, I know, I know, as usual I jumped in with both feet without checking the depth of the water. I could cut it with great difficulty using a carbide and taking no more than .010 at a pass. That was tedious and I wasn't sure if my patience or carbide inserts would wear out first. What to do?:bitingnails:

Ah-ha! I thinks, I have a friend who has a 'chop' saw (Abrasive cut off saw) I will approach today and see if it will handle this spindle. Should cut through it and anneal the end somewhat to make it more amenable to machining. (Hear I go again assuming) I don't know if his saw will handle this, if he'll want to let me do this with his saw or if he's even going to be home today.

So this project is on hold for the time being, whether that be long or short. But as I solve this problem and move on I'll post some photos (yes I've been taking them) of how things went.

So far it's a mild 'FUBAR' defrugaltie..