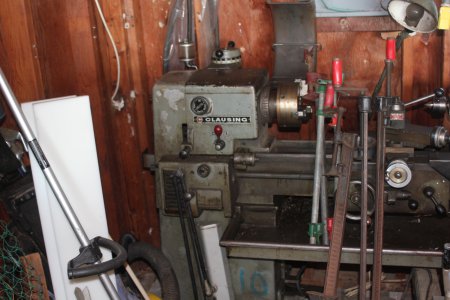

Back in March of this year, I bought a number of tools from a local estate. One of my favorites is the Clausing 5913, 12x36 lathe, which came with a full compliment of chucks and collets, taper attachment, steady and follow rest, etc. Unfortunately, no metric threading setup (which requires a new quadrant and some gears, and is impossible to find). Here's how it sat when I bought it, and me getting it into my garage workshop:

It seemed to be in pretty great shape, so I mostly just changed the headstock and apron oils, wiped it down a bit, and lubed it. The variable-speed drive, which can be an issue on these, appears to be in fine shape:

I made a spanner to turn the chuck retention collar:

I modified some shelving from the prior owner to make a storage cart:

I modified a shelving unit to hold tools:

The lathe has been great and I really like it. The taper attachment is a little crusty and there's sometimes a bit of smoothness lacking from the cross-slide screw, so I decided to disassemble from the carriage up and make sure everything is clean and as well cared for as possible. That was last night, and it seems pretty good to me. I'll be cleaning up some parts as I reassemble them, and replacing the felt wipers.

The parts:

Up close on the cross slide and its gib:

Up close on the carriage ways:

So there's a bit of scoring on the ways, but nothing major, and it doesn't seem all that worn. I have not measured anything on the lathe since leveling the bed to remove twist.

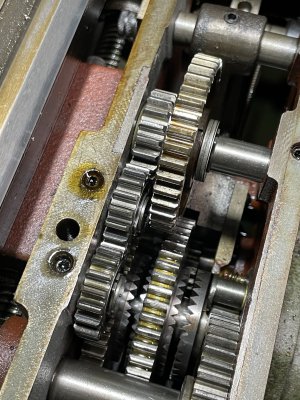

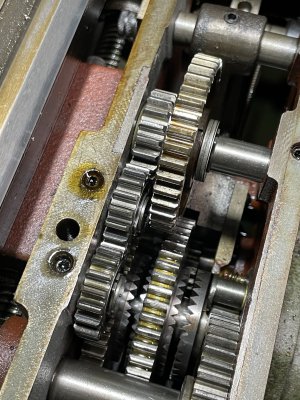

Here's the apron gearbox, which looks perfect to me and I won't be taking it apart further:

I just thought some of you may enjoy seeing the pictures. I welcome any advice while I have it apart. There don't seem to be many things I should do besides clean and reassemble with the new way wipers. I have a new seal for where the cross-feed screw goes through the carriage, though I've not seen any leaks.

-jason

It seemed to be in pretty great shape, so I mostly just changed the headstock and apron oils, wiped it down a bit, and lubed it. The variable-speed drive, which can be an issue on these, appears to be in fine shape:

I made a spanner to turn the chuck retention collar:

I modified some shelving from the prior owner to make a storage cart:

I modified a shelving unit to hold tools:

The lathe has been great and I really like it. The taper attachment is a little crusty and there's sometimes a bit of smoothness lacking from the cross-slide screw, so I decided to disassemble from the carriage up and make sure everything is clean and as well cared for as possible. That was last night, and it seems pretty good to me. I'll be cleaning up some parts as I reassemble them, and replacing the felt wipers.

The parts:

Up close on the cross slide and its gib:

Up close on the carriage ways:

So there's a bit of scoring on the ways, but nothing major, and it doesn't seem all that worn. I have not measured anything on the lathe since leveling the bed to remove twist.

Here's the apron gearbox, which looks perfect to me and I won't be taking it apart further:

I just thought some of you may enjoy seeing the pictures. I welcome any advice while I have it apart. There don't seem to be many things I should do besides clean and reassemble with the new way wipers. I have a new seal for where the cross-feed screw goes through the carriage, though I've not seen any leaks.

-jason

Mine came with the optional beam clamp accessory package , along with a bunch of other crap .

Mine came with the optional beam clamp accessory package , along with a bunch of other crap .