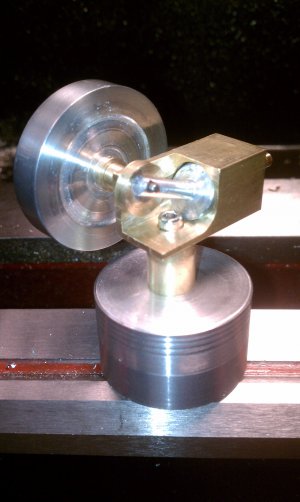

Barstock kit by www.lineymachine.com but I bought it at www.ministeam.com

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my first machining project

- Thread starter joegamma1

- Start date

B

BRIAN

Forum Guest

Register Today

Lovely job just the thing for a first project, I almost bit off more than i could chew.so you did it right.

Are you going to try a small boiler to power it ,KERV made a nice one for his last engine its worth looking at.

CONGRATULATIONS BRIAN.

Are you going to try a small boiler to power it ,KERV made a nice one for his last engine its worth looking at.

CONGRATULATIONS BRIAN.

Thanks fellas,

I only have plans to power it with air, I think steam would cause a burn hazard as the piston tilts to release compression at the bottom of the stroke.

my goal is to make mini hit-n-miss engines, have wanted to start doing this for years.

Bought the micro mill from HF 2-3 years ago and just picked up the 7x10 this last month-I figured I wasn't getting any younger, better get to it.

Wish I could post a vid from my phone so you guys could see it run.

And for scale: that little counter sunk screw is a 2-56.

I only have plans to power it with air, I think steam would cause a burn hazard as the piston tilts to release compression at the bottom of the stroke.

my goal is to make mini hit-n-miss engines, have wanted to start doing this for years.

Bought the micro mill from HF 2-3 years ago and just picked up the 7x10 this last month-I figured I wasn't getting any younger, better get to it.

Wish I could post a vid from my phone so you guys could see it run.

And for scale: that little counter sunk screw is a 2-56.

Yes, I hadn't seen one either. But I thought it would be simple enough. Liney machine has a couple other air engine as well.

I'm thinking of scaling this kit up x2 and trying it again.

They send a piece of 3/8" x 1" bar stock for the piston/rod but I ended up having to over bore the cylinder and use some aluminium barstock. The 2nd one of those worked great.

I would suggest this kit to anyone.

I did the work on a HF micro mill and a HF 7x10

Thanks again for everyone's comments and encouragement

Joe

I'm thinking of scaling this kit up x2 and trying it again.

They send a piece of 3/8" x 1" bar stock for the piston/rod but I ended up having to over bore the cylinder and use some aluminium barstock. The 2nd one of those worked great.

I would suggest this kit to anyone.

I did the work on a HF micro mill and a HF 7x10

Thanks again for everyone's comments and encouragement

Joe

Pretty neat, so that cylinder body is a piece of 1/2" square? I wonder just how small that design can be taken? Without the complications of a valve arrangement, and no crosshead etc. it could be made really small. I believe that engine design might be a version of the Uniflo principal, where the piston uncovers the exhaust port and only the steam inlet is valve operated. How does it run, have you tested it yet? I'm amazed it runs without a timed inlet valve.