- Joined

- Feb 22, 2012

- Messages

- 924

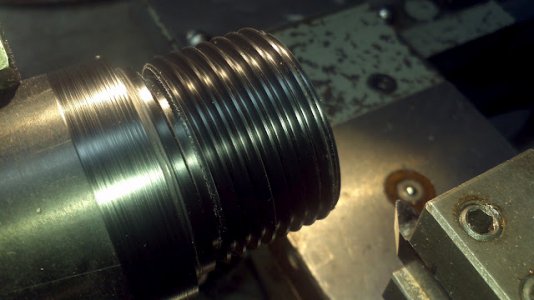

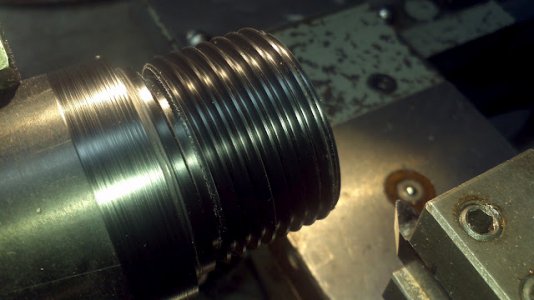

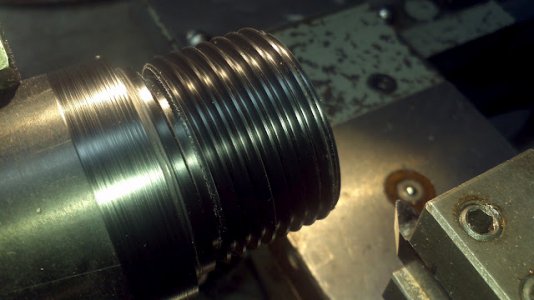

I am planning on making some chucks/plates/adaptors for the lathe spindle, and it being a not so common size (1-3/4x8tpi) I figured I might as well make a copy of the spindle to use as a fit-testing plug.

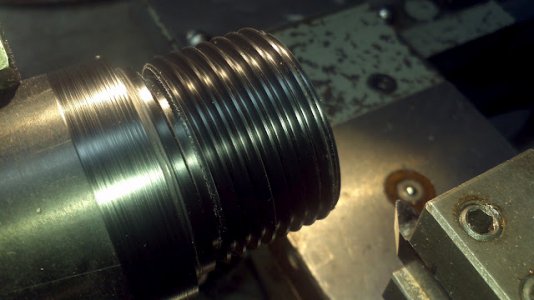

Fits like a glove and I'm very pleased with this first experience:

I can now use this to test for fit if I'm making adaptors/plates/chucks for the lathe while the part being worked on is still chucked on the lathe without losing the settings.

- I turned some UHMW to 1-3/4" the length of the spindle, including the registration shoulder.

- I cut a relief notch 1" from the edge (where the threading on the spindle ends)

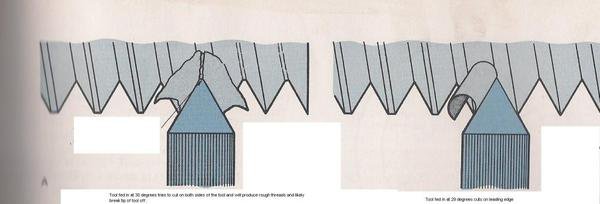

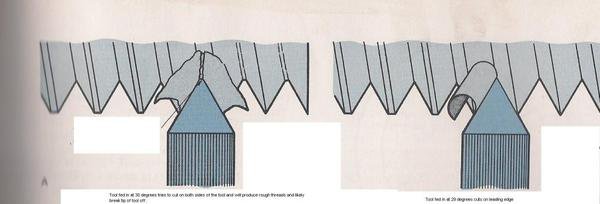

- I threaded 8tpi, and used a small(er) jacobs headstock chuck to test for fit

- chamfered the end

Fits like a glove and I'm very pleased with this first experience:

I can now use this to test for fit if I'm making adaptors/plates/chucks for the lathe while the part being worked on is still chucked on the lathe without losing the settings.