- Joined

- Dec 13, 2016

- Messages

- 142

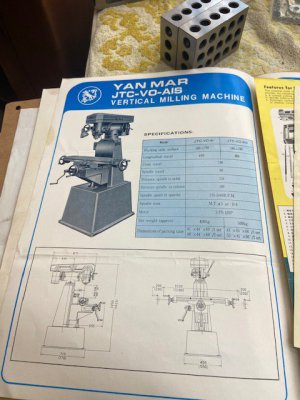

Sorry Not getting back sooner It’s been of week. Here is measurements you are looking for.

From the wall to tips of front Y-axis handle is about 45”

With X-axis crank all the to right is about 33.5” and to the left also about 33.5”

With belt cover open it is about 72” to highest point with bottom of my base is off floor by 1”. Using a Shop Fox rolling base from Grizzly.

You might add another 1 to 2” for removing the drawbar.

Hope this helps you out. I have small floor space location next to my lathe. The mill was going to stick out about 18” past the lathe. Decide to locate it on the other side of the lathe in a corner. This should work out OK.

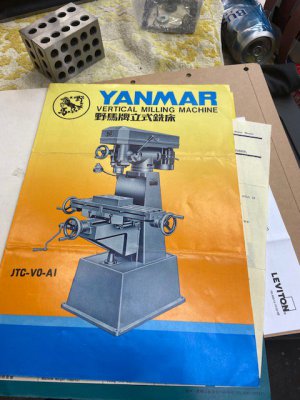

Got this mill off CL back in March down the road from you in Tyson Corners next to Tesla car dealership.

Bob G.

From the wall to tips of front Y-axis handle is about 45”

With X-axis crank all the to right is about 33.5” and to the left also about 33.5”

With belt cover open it is about 72” to highest point with bottom of my base is off floor by 1”. Using a Shop Fox rolling base from Grizzly.

You might add another 1 to 2” for removing the drawbar.

Hope this helps you out. I have small floor space location next to my lathe. The mill was going to stick out about 18” past the lathe. Decide to locate it on the other side of the lathe in a corner. This should work out OK.

Got this mill off CL back in March down the road from you in Tyson Corners next to Tesla car dealership.

Bob G.

Attachments

Last edited: