Hi everyone, I hope that's the right section.

I heard there's tariffs increase for the 10th November, so I went out to build for 3rd time my cart from Little Machine Shop and I want get started in hobby machining.

That or PM-1030V which might make me run out of budget ( 3500 $ USD or 4500 $ CAD ), I live in Canada so I can't just place more than one order from USA.

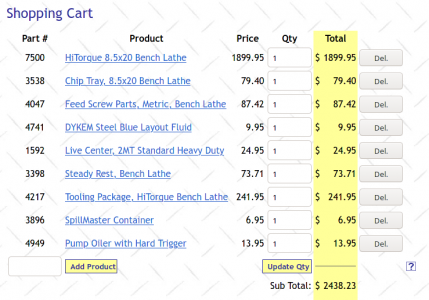

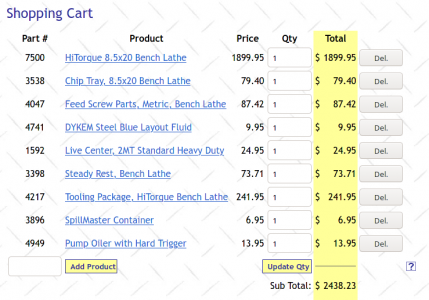

My cart, anything important is missing ? Also, I want my lathe to be metric.

I know there's posts that warn to not downgrade the choice of metal lathe to something smaller in order to meet the budget, so that's what I did go with LMS 8.5x20 lathe above the LMS 7x16 or Grizzly 7x14 for these features that sets it apart from 7x lathes. This lathe should be good for my beginner projects as bored IT student. Also, I don't need DRO right away as I want to learn to work the metal lathe.

Well, I have open mind to any suggestions. Yet, I can't know which the right question to ask.

Thanks

I heard there's tariffs increase for the 10th November, so I went out to build for 3rd time my cart from Little Machine Shop and I want get started in hobby machining.

That or PM-1030V which might make me run out of budget ( 3500 $ USD or 4500 $ CAD ), I live in Canada so I can't just place more than one order from USA.

My cart, anything important is missing ? Also, I want my lathe to be metric.

I know there's posts that warn to not downgrade the choice of metal lathe to something smaller in order to meet the budget, so that's what I did go with LMS 8.5x20 lathe above the LMS 7x16 or Grizzly 7x14 for these features that sets it apart from 7x lathes. This lathe should be good for my beginner projects as bored IT student. Also, I don't need DRO right away as I want to learn to work the metal lathe.

Well, I have open mind to any suggestions. Yet, I can't know which the right question to ask.

Thanks