So almost exactly 1yr after the purchase of the mill I've decided to convert it to CNC.

Let me get some things out of the way first, this is going to be a cheap build. Yes in a perfect world I'd have a Tormach 1100 but that would be an overkill for how much I'll use it. Nope, not even going to convert it to ballscrews, at least not yet.

Goals: cheap, quick and easy

Hopefully, this conversion will help someone out who has wanted to do this but wasn't sure about it, didn't know how, or thought it was too expensive. If it all blows up, it'll at least provide some entertainment! :lol_hitti

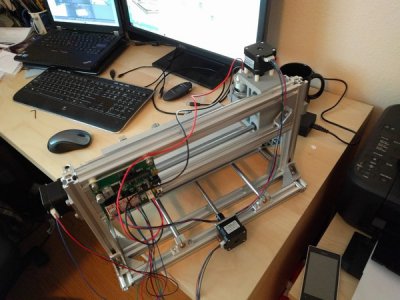

How the mill sits today:

Let me get some things out of the way first, this is going to be a cheap build. Yes in a perfect world I'd have a Tormach 1100 but that would be an overkill for how much I'll use it. Nope, not even going to convert it to ballscrews, at least not yet.

Goals: cheap, quick and easy

Hopefully, this conversion will help someone out who has wanted to do this but wasn't sure about it, didn't know how, or thought it was too expensive. If it all blows up, it'll at least provide some entertainment! :lol_hitti

How the mill sits today: