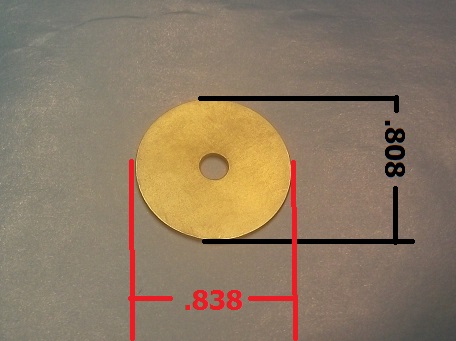

I need to find someone that can machine me a punch/die set up that will punch these discs from .032 sheet brass.

The center hole is .143"

The o.d. is not round.

It goes from .808 on 2 sides to .838 on the opposite 2 sides so it's oval.

If that isn't do-able does anyone here have a laser, water jet or cnc router that can cut these?

This is the last new one I have and I need some more ASAP I have new brass sheet in stock

.

The center hole is .143"

The o.d. is not round.

It goes from .808 on 2 sides to .838 on the opposite 2 sides so it's oval.

If that isn't do-able does anyone here have a laser, water jet or cnc router that can cut these?

This is the last new one I have and I need some more ASAP I have new brass sheet in stock

.