- Joined

- Nov 4, 2017

- Messages

- 12

Hello

Greetings everyone,

I always wanted to have small work shop. it started with Taig lathe, drill press, upgrade it to Sieg C2 lathe. But as you know, the Sieg C2 lathe was make me headache with plastic gear in headstock, the tailstock is not comfortable. So in the past 3-4 years, i have been watching scrap yard/ second hand market in my city, I was wait for the vintage lathe, but i get another stuff too, milling, small precision drill press, and others.

if you familiar with one of the machines below, that would be helpfull to me, (german for JMB , and italian for ro-sa drill press)

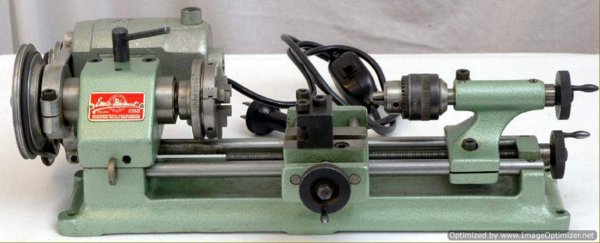

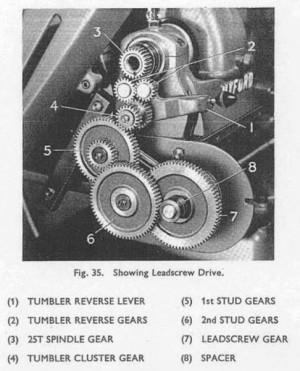

1. myford ML7 lathe (made in england)

lovely lathe, the tailstock was sooo nice and sturdy, i have question about this lathe, when i bought this lathe, i got what it has on it, so i the gears was uncomplete, can anyone notice what size gear that i need? , and there's cut on spindle thread, is that oke or i need to replace it and bought the new one ( 300 pounds that's expensive) from myford.co.uk. and the last question is about, is that imperial or metric hex screw that used in myford lathe?

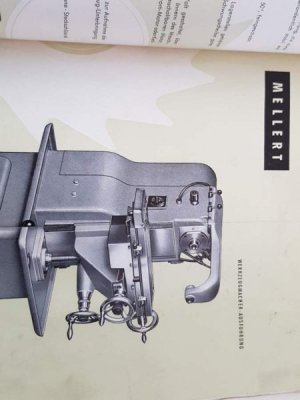

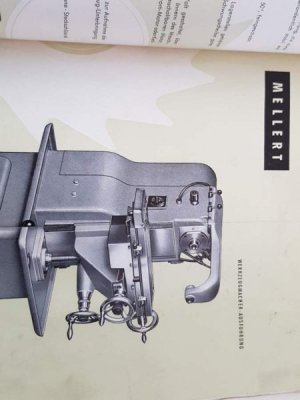

2. JMB fräsmaschine (made in W. germany)

JMB fräsmaschine / JMB universal milling machine. when i bought this machine, there's nothing in internet about this machine in english, it so i contact Tony from lathes.co.uk to add thread about this machine. if everyone in here know anything about this, that would be nice. AND THERE's SMALL CHUNK on the cast iron body, anybody know anything about cast iron weld? if everyone have this machine, just curious about the weight of vertical attachment.

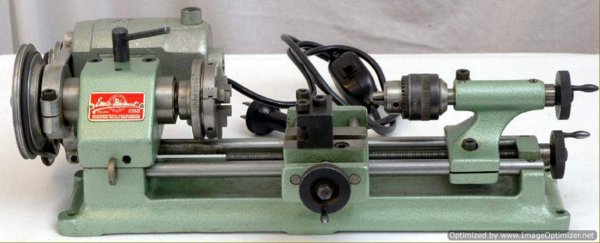

3. Unimat MK-IIB lathe (made in Austria)

that's one of rare of unimat lathe, with full cast iron base and body. i think i need to replace the steel rod.

4. Ro-Sa micro drill press (made in Italy)

it's same with JMB fräsmaschine, it's hard to find information about this machine, i have google it with "micromeccanica microtrapano RC" and it take me to orologiko.it , one of the italian wathcmaker forum, i can't access it, so if everyone here is italian, that would be helpfull for me. i dont know the taper of that , i do confused with JT1 and B10.

http://www.nielsmachines.com/en/sold-ro-sa-sensitive-precision-drilling-machine-f.html

and the right corner was machine that used for jevelery stuff, i plan to make surface grinder with that and use LM motion guide for table. So this is it, as long as i know, German and austrian use metric screw, and i'm not sure about italian and england?

best regards

Ali

Greetings everyone,

I always wanted to have small work shop. it started with Taig lathe, drill press, upgrade it to Sieg C2 lathe. But as you know, the Sieg C2 lathe was make me headache with plastic gear in headstock, the tailstock is not comfortable. So in the past 3-4 years, i have been watching scrap yard/ second hand market in my city, I was wait for the vintage lathe, but i get another stuff too, milling, small precision drill press, and others.

if you familiar with one of the machines below, that would be helpfull to me, (german for JMB , and italian for ro-sa drill press)

1. myford ML7 lathe (made in england)

lovely lathe, the tailstock was sooo nice and sturdy, i have question about this lathe, when i bought this lathe, i got what it has on it, so i the gears was uncomplete, can anyone notice what size gear that i need? , and there's cut on spindle thread, is that oke or i need to replace it and bought the new one ( 300 pounds that's expensive) from myford.co.uk. and the last question is about, is that imperial or metric hex screw that used in myford lathe?

2. JMB fräsmaschine (made in W. germany)

JMB fräsmaschine / JMB universal milling machine. when i bought this machine, there's nothing in internet about this machine in english, it so i contact Tony from lathes.co.uk to add thread about this machine. if everyone in here know anything about this, that would be nice. AND THERE's SMALL CHUNK on the cast iron body, anybody know anything about cast iron weld? if everyone have this machine, just curious about the weight of vertical attachment.

3. Unimat MK-IIB lathe (made in Austria)

that's one of rare of unimat lathe, with full cast iron base and body. i think i need to replace the steel rod.

4. Ro-Sa micro drill press (made in Italy)

it's same with JMB fräsmaschine, it's hard to find information about this machine, i have google it with "micromeccanica microtrapano RC" and it take me to orologiko.it , one of the italian wathcmaker forum, i can't access it, so if everyone here is italian, that would be helpfull for me. i dont know the taper of that , i do confused with JT1 and B10.

http://www.nielsmachines.com/en/sold-ro-sa-sensitive-precision-drilling-machine-f.html

and the right corner was machine that used for jevelery stuff, i plan to make surface grinder with that and use LM motion guide for table. So this is it, as long as i know, German and austrian use metric screw, and i'm not sure about italian and england?

best regards

Ali