Hi all,

I need some help deciding between the G0757 and G0796.

G0757

http://www.grizzly.com/products/Variable-Speed-Horizontal-Vertical-Mill-with-DRO/G0757Z

G0796

http://www.grizzly.com/products/9-X-49-Vertical-Mill-with-Power-Feed-and-DRO/G0796

G0796 is essentially a Bridgeport style mill. Similar features and capabilities as everyone is used to seeing.

The G0757 is a knee mill with the addition of horizontal milling (run off a separate 2HP motor).

I am hobby machinist and occasionally I make parts for my day job, in hopes that the hobby will pay for itself. We make customized equipment, so some of the parts we use are all very similar, but different enough that it would be worthwhile to make some blanks and then modify them myself as needed.

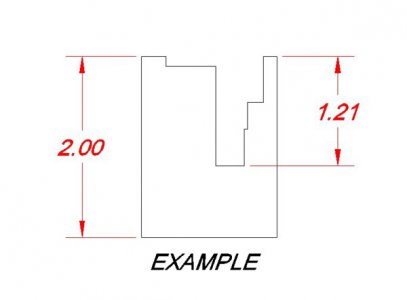

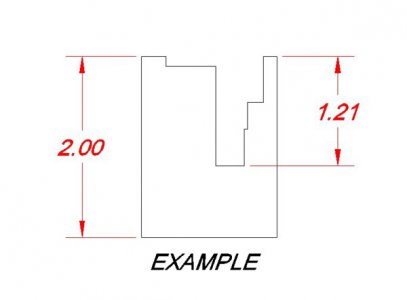

The main part I'm looking at making is typically 24" long and has some type of grooved shape in it, similar to the attached image. I think this would be perfect for a horizontal mill. I'd be able to get a lot of the material removed in a single pass, instead of picking away at it with a long, small diameter end mill.

My concerns for it are:

No powered quill feed.

The damn table ROTATES. Pretty cool for the horizontal milling, but, I'd rather swivel the vise. But I worry how much of a pain is going to be to get trammed. Will this be a weak link that works loose and allows for chatter? I'm not familiar with this feature at all, and I wonder if it does more bad than good.

The table travel is only 23.5". I already plan to use a pair of matched vises on the table to hold the long parts, but now, I'd be looking at having to set it up and move the part for every cut. I'm not sure I'm skilled enough to carry on a cut after moving the vise without it being obvious.

I'm also not as keen on the max 2300 RPM spindle, but both mills are similar. So unless I added VFD, I'm stuck in that range anyways.

I have no tooling for horizontal milling and no experience with it.

I'm coming from using a Rong Fu 45 style mill and decided that I'm spending enough time in front of my mill and have enough room in my garage, that a full size knee mill would be worth while.

Any advice would be much appreciated.

I need some help deciding between the G0757 and G0796.

G0757

http://www.grizzly.com/products/Variable-Speed-Horizontal-Vertical-Mill-with-DRO/G0757Z

G0796

http://www.grizzly.com/products/9-X-49-Vertical-Mill-with-Power-Feed-and-DRO/G0796

G0796 is essentially a Bridgeport style mill. Similar features and capabilities as everyone is used to seeing.

The G0757 is a knee mill with the addition of horizontal milling (run off a separate 2HP motor).

I am hobby machinist and occasionally I make parts for my day job, in hopes that the hobby will pay for itself. We make customized equipment, so some of the parts we use are all very similar, but different enough that it would be worthwhile to make some blanks and then modify them myself as needed.

The main part I'm looking at making is typically 24" long and has some type of grooved shape in it, similar to the attached image. I think this would be perfect for a horizontal mill. I'd be able to get a lot of the material removed in a single pass, instead of picking away at it with a long, small diameter end mill.

My concerns for it are:

No powered quill feed.

The damn table ROTATES. Pretty cool for the horizontal milling, but, I'd rather swivel the vise. But I worry how much of a pain is going to be to get trammed. Will this be a weak link that works loose and allows for chatter? I'm not familiar with this feature at all, and I wonder if it does more bad than good.

The table travel is only 23.5". I already plan to use a pair of matched vises on the table to hold the long parts, but now, I'd be looking at having to set it up and move the part for every cut. I'm not sure I'm skilled enough to carry on a cut after moving the vise without it being obvious.

I'm also not as keen on the max 2300 RPM spindle, but both mills are similar. So unless I added VFD, I'm stuck in that range anyways.

I have no tooling for horizontal milling and no experience with it.

I'm coming from using a Rong Fu 45 style mill and decided that I'm spending enough time in front of my mill and have enough room in my garage, that a full size knee mill would be worth while.

Any advice would be much appreciated.