- Joined

- Jan 7, 2016

- Messages

- 3,279

Update:

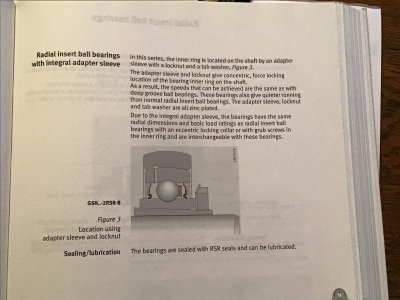

Following your guys' advice, I found a couple of bearing suppliers about an hour away. I called both of them. One was not helpful, but the other bent over backward to help me out, along with educating me on bearings. The original bearings had an eccentric locking collar, but I was informed that a concentric one would be better for my needs. The eccentric lock could possibly introduce a very slight off-center position of the shaft within the bearing (I am assuming a thou or so?). I ordered two pillow block bearings from him with concentric collar locks that have dimensions very close to the originals. They should be here in a day or two.

As well as my sander has worked over the years, one problem consistently showed up: "chatter" marks in the boards. I attributed this to the bearings, but as I dismantled this machine, I discovered more issues. The biggie was my sandpaper take-up mechanism. I thought that I had it balanced (using material calculations) but when I took it off of the sanding drum and set it on an actual balancer, it was way off. A little time on my mill and some counterweights solved that issue. The final part of the vibration puzzle is the drive belts from the main motor. I decided to replace the standard v-belts with a segmented belt. Accu-Link belts. That system should be here in a day or two also.

Following your guys' advice, I found a couple of bearing suppliers about an hour away. I called both of them. One was not helpful, but the other bent over backward to help me out, along with educating me on bearings. The original bearings had an eccentric locking collar, but I was informed that a concentric one would be better for my needs. The eccentric lock could possibly introduce a very slight off-center position of the shaft within the bearing (I am assuming a thou or so?). I ordered two pillow block bearings from him with concentric collar locks that have dimensions very close to the originals. They should be here in a day or two.

As well as my sander has worked over the years, one problem consistently showed up: "chatter" marks in the boards. I attributed this to the bearings, but as I dismantled this machine, I discovered more issues. The biggie was my sandpaper take-up mechanism. I thought that I had it balanced (using material calculations) but when I took it off of the sanding drum and set it on an actual balancer, it was way off. A little time on my mill and some counterweights solved that issue. The final part of the vibration puzzle is the drive belts from the main motor. I decided to replace the standard v-belts with a segmented belt. Accu-Link belts. That system should be here in a day or two also.