- Joined

- Feb 4, 2013

- Messages

- 103

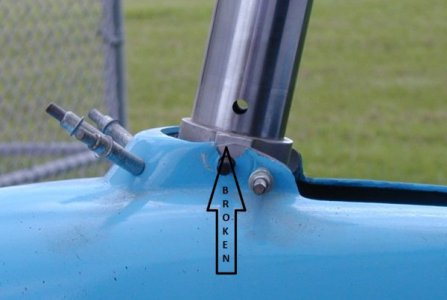

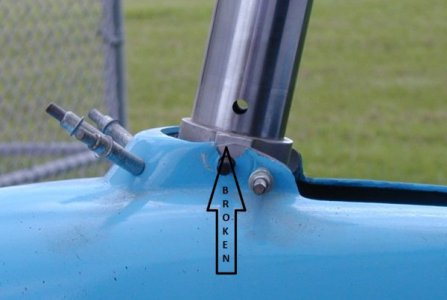

I’m working on a little two-seat Cessna 150 and its fiberglass nosewheel pant has damage at two of its attachment holes. The pant is predominately held on by the wheel’s axle but is prevented from rotating around the axle by an “anti-rotation” bolt at the top (see picture 1). It’s the two anti-rotation boltholes in the pant that are damaged (see pic 2).

The wheelpant is constructed of common (i.e. mid-1970s, non-exotic) fiberglass that is, otherwise, in very good condition. The 7/16 diameter axle holes are about 1/4” thick and in good shape but the thinner (~ 1/16” thick) 1/4” dia anti-rotation boltholes have broken out at their tops. (Picture 2) I only have room for a 1/16” thick reinforcement and originally figured that a metal doubler (temporarily held in place by clecos in picture 3) would be stronger than 1/16” more fiberglass; however, I've since heard that trying to bond a steel or aluminum reinforcement to fiberglas wouldn't work as well as I thought, according to a local boat repairer.

A stiffener made out of carbon fiber has been suggested but I know almost nothing about working with CF. Can anyone here teach this old guy a new trick?

Thanks,

Harvey

The wheelpant is constructed of common (i.e. mid-1970s, non-exotic) fiberglass that is, otherwise, in very good condition. The 7/16 diameter axle holes are about 1/4” thick and in good shape but the thinner (~ 1/16” thick) 1/4” dia anti-rotation boltholes have broken out at their tops. (Picture 2) I only have room for a 1/16” thick reinforcement and originally figured that a metal doubler (temporarily held in place by clecos in picture 3) would be stronger than 1/16” more fiberglass; however, I've since heard that trying to bond a steel or aluminum reinforcement to fiberglas wouldn't work as well as I thought, according to a local boat repairer.

A stiffener made out of carbon fiber has been suggested but I know almost nothing about working with CF. Can anyone here teach this old guy a new trick?

Thanks,

Harvey

Last edited: