For purchased arbors, Sierra American is very good for a reasonable price. Even better is a Martindale holder. Both have thinner caps to allow better access and they're hardened and ground for accuracy.

I would buy a straight shank holder, not an integral R8, because you often need to move that holder up or down in the collet a tiny bit to get the saw where you want it in Z.

Making your own is the best option but you need to be able to turn pretty accurately. If you're not confident in this, buy one from Sierra American or someone you prefer.

Saws come with all sorts of sized holes - 1/2" is most common for the thinner blades, 1" is common for bigger saws and 5/8" or 3/4" are also common but the choice of saws may be more limited. Many saws come with key slots that you will probably never use in the thinner saw thicknesses. Keep in mind that the bigger the saw, the more likely it is to spin in the arbor with a heavy cut. For example, a 4" saw with a 1/2" arbor hole is likely to spin when taking a big cut.

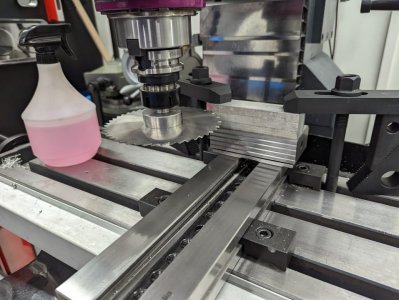

Slitting saws are meant to cut to full depth from the start. You do not need to sneak up on the final depth; set the depth and go in one pass. Use a lot of cutting oil. When feeding manually, feed at a rate that allows you to feel a slight resistance to the feed; it will be faster than you think it should be. This allows the saw to cut continuously without binding or chattering.

Speeds are important for slitting saws and it depends on the material, the size of the saw and number of teeth on the blade. Harder materials, higher tooth count and bigger saw diameter = slower speeds. My preference is to start slow and increase speed as tolerated. You are okay with silver or light amber chips in steel but you don't ever want blue chips as this much heat can ruin the temper of the blade.

I'm attaching a guide from Martindale that has some really good info.

Someone on here bought a few of the smaller arbors a while back , not sure who though any more . They call these stub arbors FWIW .

Someone on here bought a few of the smaller arbors a while back , not sure who though any more . They call these stub arbors FWIW .

Someone on here bought a few of the smaller arbors a while back , not sure who though any more . They call these stub arbors FWIW .

Someone on here bought a few of the smaller arbors a while back , not sure who though any more . They call these stub arbors FWIW .