- Joined

- Oct 29, 2020

- Messages

- 13

Need help understanding differences between collets: ER32 vs. ER24, ect. I have a 10x22 Grizzly G0602 lathe with MT4 in the head and would like a collet adapter that wont brake the bank.

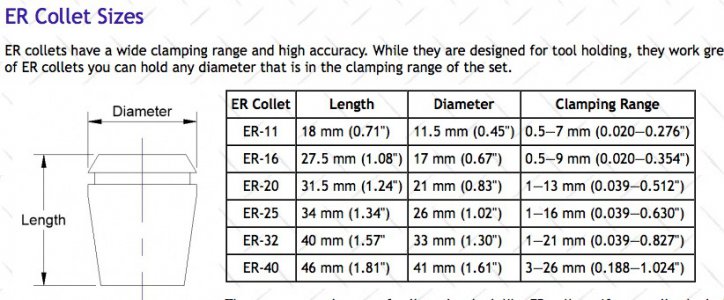

The thread on the 602 spindle is rather unique. It is a 1-3/4-8 tpi. I ordered a new backing plate as a replacement part from Grizzly. P0606054-2 for the 5" backplate and P0602055-3 for the 6" backplate.The differences between the ER collets are size: a bigger number equals a range of collets that are larger.

Adding an ER adapter with an MT taper will require a drawbar to ensure that the tool is secure in the spindle.

This sort of adapter is often found in mills where the collet is used for toolholding.

Using that type on the lathe eliminates one of the advantages of the ER system for workholding, which is the ability to pass

long pieces of stock through the collet. It may cost more, but a better solution is the use of a collet chuck

on a backing plate. Shars sells an "adjust true" style collet chuck that is reasonably priced. I don't know

what spindle mount your Griz has, so can't advise on that.

All good info guys, thanks. I think ill want a 5c collet chuck so I can run stock through the head. Or is that a possibility with the ER types? Also, someone mentioned that 5c are actually designed for work holding where the ER are

for tool holding? Maybe not an issue for benchtop lathe.