- Joined

- Jul 22, 2013

- Messages

- 14

I'm now sure where to post this, so I'll start here.

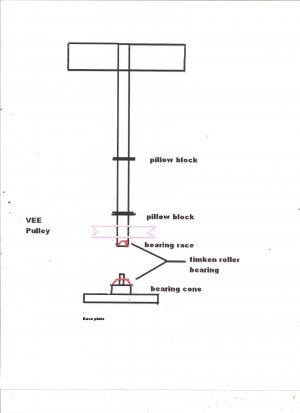

I'm building a project that is a rotary antenna. I have a 1" OD shaft that is the mast. The mast runs vertical and will be supported by one or more pillow blocks. A stepper motor will be driving the shaft from the bottom end, connected by a flexible coupling to relieve an stress on the motor.

My question is how to support the shaft vertically. I know I need some kind of thrust bearing on the bottom, but I don't know how to do that while still driving the shaft/mast with the motor.

One thought I had is to use the adapter I'll need to get from the motor drive shaft diameter to the mast diameter. If I turn a flat face on it I could use that as one race against a thrust bearing link this;

https://sdp-si.com/eStore/Catalog/Group/486

Am I headed in the right direction or is there a better way to do this?

Thanks!

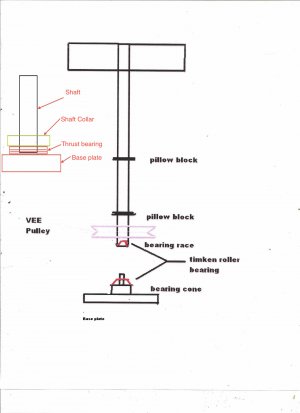

I'm building a project that is a rotary antenna. I have a 1" OD shaft that is the mast. The mast runs vertical and will be supported by one or more pillow blocks. A stepper motor will be driving the shaft from the bottom end, connected by a flexible coupling to relieve an stress on the motor.

My question is how to support the shaft vertically. I know I need some kind of thrust bearing on the bottom, but I don't know how to do that while still driving the shaft/mast with the motor.

One thought I had is to use the adapter I'll need to get from the motor drive shaft diameter to the mast diameter. If I turn a flat face on it I could use that as one race against a thrust bearing link this;

https://sdp-si.com/eStore/Catalog/Group/486

Am I headed in the right direction or is there a better way to do this?

Thanks!