- Joined

- Sep 23, 2020

- Messages

- 80

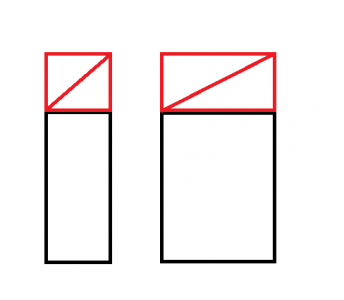

I've a tool post mill attached to the compound of my lathe and wanted to make a helix pattern on a tube. I've looked around for online calculators and formula's but am just getting more confused and frustrated. None of the calculations i tried was anywhere close to what i need. A picture says thousand words so here's what i'm trying to achieve...

So as you can see i'm trying to make a helix in increments / one cut at a time. The cuts on the right side in the right pic are my first cuts that were messed up calcs. I literally stumbled on the dimensions that i needed for it all to line up and still don't know the calculation. So if I use a different diameter stock it won't work out so neat right?

My set up is - stock diameter 24.94mm , compound slide 30 degrees, move carriage 15mm and roll the stock 30 degrees for each successive cut.

Does anyone know a formula i can use for different diameter stock?

So as you can see i'm trying to make a helix in increments / one cut at a time. The cuts on the right side in the right pic are my first cuts that were messed up calcs. I literally stumbled on the dimensions that i needed for it all to line up and still don't know the calculation. So if I use a different diameter stock it won't work out so neat right?

My set up is - stock diameter 24.94mm , compound slide 30 degrees, move carriage 15mm and roll the stock 30 degrees for each successive cut.

Does anyone know a formula i can use for different diameter stock?