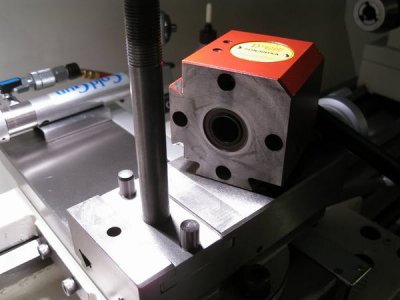

For the past several years I have tried to knurl using the old familar rocker type and the one that came with my QCTP tool post. In either case I continually have had poor results. There are those that believe the scissor version is the best and I have to agree. The photo above shows a homemade scissor type knurling tool that I made and it has for the first time shown in some decent fashion,reasonable results.

The basic frame is made using 1018 CRS,the lead screw I believe is 12L14. Both the top and bottom bars are attached to the "T" bkt with grooved pins (for lack of a better description)that are secured with what I'm told are called "E" clips. There is some side play which brings up a question;how critical is that characteristic should this be a tight fit?

ANY COMMENTS SO FAR?

The homemade screws shown above are also made using 1018 and if you look close enough you could detect ware.

Question;Would it be wise to temper these screws

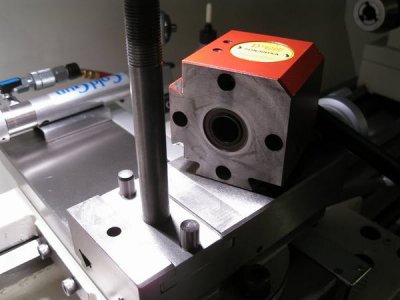

This photo shows what the knurler can do,I purchased two sets of knurlers,medium and coarse. The medium knurl doesn't look too bad,on the other hand the coarse leaves something to be desired some of the diamond pattern looks pitted. I purchased the two pair of knurlers from the same supplier OD = .750 , ID = .250 , HT = .375 The ID of the coarse knurlers is .015"larger then the medium set,could this be a problem

ANY COMMENTS

I'm still learning any comments suggestions will be greatly appreciated