- Joined

- Jan 29, 2014

- Messages

- 156

I find myself in need of a collet stop for 2A collets which do not have an internal thread.

The cavity in the collet is 0.680" in diameter and about 2" long.

I need some ideas on how to make a simple yet functional collet stop. I would like a stop that fits inside the collet and not on the collet closer.

The google has provided me with a few examples, but I am hoping someone on this board has a better idea:

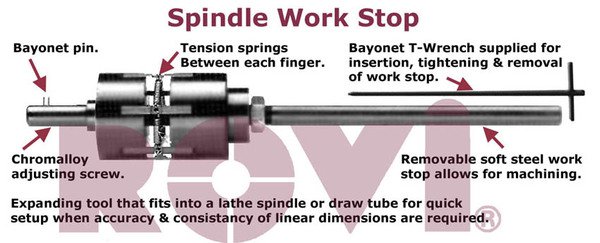

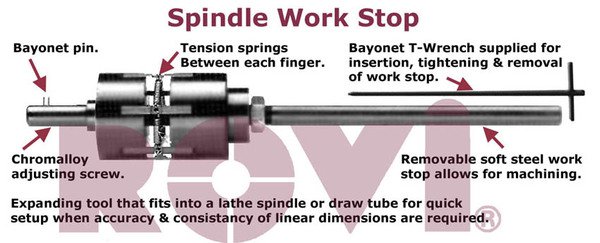

This example is a bit complicated, not sure how I would make the split part:

This example is for a 3C collet (even smaller than mine) but I am not entirely sure how it works. The only thing I can find about it is this picture:

This is a Speed Stop, which is made here in town, but I don't think they make one small enough for my collet. (I tried to email them, but the address on their website does not work):

This example is for a shaublin 20mm collet that uses ball bearings and tapered shaft to grip the inside of the collet. I have no idea how I would drill a hole that would allow the ball bearing to extend to the collet, but not fall out completely.

This commercial collet stop looks way too complicated to scale down to fit inside my collet:

I appreciate your help.

The cavity in the collet is 0.680" in diameter and about 2" long.

I need some ideas on how to make a simple yet functional collet stop. I would like a stop that fits inside the collet and not on the collet closer.

The google has provided me with a few examples, but I am hoping someone on this board has a better idea:

This example is a bit complicated, not sure how I would make the split part:

This example is for a 3C collet (even smaller than mine) but I am not entirely sure how it works. The only thing I can find about it is this picture:

This is a Speed Stop, which is made here in town, but I don't think they make one small enough for my collet. (I tried to email them, but the address on their website does not work):

This example is for a shaublin 20mm collet that uses ball bearings and tapered shaft to grip the inside of the collet. I have no idea how I would drill a hole that would allow the ball bearing to extend to the collet, but not fall out completely.

This commercial collet stop looks way too complicated to scale down to fit inside my collet:

I appreciate your help.