Post a picture of what your talking about, we don't have crystal balls. Do-All stopped making grinders, but the do make band saws in Des Plaines IL. If it is a cage around ball bearings and they roll on hardened ways, then most likely they are Phenolic. If it is a plat strip glued on it is what the others said. Turcite B or Rulon 142. These are guy's I buy from.

https://www.tstar.com/

Hi Richard,

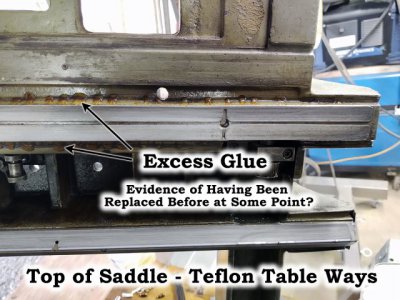

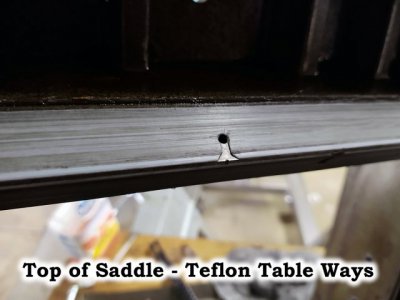

Attached are a few photos of the DoAll DH612 Surface Grinder saddle showing the “V” and “Flat” ways with the worn Teflon as well as the bottom of the saddle where it’s iron to iron.

For some reason I translated “Teflon” to “Nylon”, not sure how I made that mistake, it could be because I was researching the difference between the two materials?

It appears to me to be the standard arrangement of one “V” way and one “Flat” way, I have seen a few lathes with two “V” ways but most machines are the one “V” and one “Flat” way.

I realize that DoAll does not make anything but sawing machines these days but I was hoping that somebody might know of someone that makes aftermarket replacement parts for obsolete DoAll machines.

My question was: “Does anyone have a source for DoAll surface grinder parts?” and is why I didn’t post any photos of the guide ways.

The fact that mine is not some sort of unique arrangement is another reason I didn’t post photos with my question.

The bottom of the saddle is iron to iron, no Teflon or PTFE and there is no apparent wear, no grooves or gouges (I’m thankful for that).

The way material is white and cuts like Polyethylene plastic, I used a sharp knife on it just to see what the shavings looked like.

I do appreciate the feedback and suggestions, especially since it’s apparent that nobody makes aftermarket parts for this machine.

Maybe you didn’t read my comment where I stated that my machine does not use caged ball bearings?

And I did state that my machine does not have Turcite or Rulon but maybe you missed that comment as well? Or maybe you feel that I don’t know the difference?

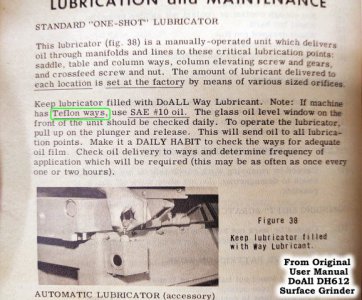

I also mentioned that the user manual indicated that the ways could be Teflon (I mistakenly called it Nylon), apparently they made two versions, one with iron to iron and one with Teflon to iron.

BTW, the user manual I have is the original that was supplied with this grinder.

In the photo showing the depth micrometer, the micrometer is tilted to the side a bit because it was hard to get a photo of it straight on but the measurement is nearly .039”, either way it should still be fairly easy to tell that the plastic material is much thicker than .010”.

To me it appears that the strips of Teflon had been replaced at some point judging by the excess glue and the uneven cuts at the oil ports, Hmmm…it could be that the last time the plastic ways were replaced they used Nylon

See photo showing both the “V” and “Flat” ways in the same photo.

Anyway, I assume that Rulon or Turcite will hold up to grinding dust/swarf as well as the Teflon did, either way, it’s better than wearing away the iron.

Note: The “V” and “Flat ways on the underside of the table appear to be in good condition with very, very little scoring (no photos of that portion).

I am curious, if your balls aren’t make of crystal, what are they made of?

Thanks for your input.

Joe