Hi again, RichardIt looks like the factory must have done it. I have never seen a DO-All with factory lined ways. If it is white, then it must be Nylon... Turcite B and Rulon 142 comes in red or aqua green that I have ever seen. Garlock made one that was or is brown. It is probably .032" plus the glue was .005" and it is worn. The straight oil grooves are bad and if you replace it fill the grooves with epoxy and then zigzag the new material and don't cut through it as it is a way the bond will fail. Shambam the original maker of Turcite went out of business because they told customers to cut the oil grooves through the material and got sued. If the material is not loose, you could leave it alone or scrape in some new oil pockets.

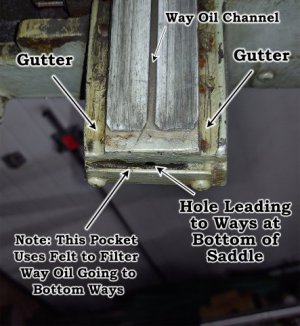

I need to explain why the oil grooves or oil channels are there in the first place, the "One Shot" oiler does not have a set of lines going to the ways on the bottom of the saddle, the method they used to get oil to the bottom ways is by those oil grooves, the oil runs down the oil groove from the "One Shot" system to the pockets on each end (as well as overrun into the gutters on the sides), so, the oil is fed into a pocket on each side of the saddle (same for the "V" way ends).

I've attached a photo showing the arrangement they used.

Having explained their arrangement, I agree that it is a bad idea and that the zig zag idea would be much better, the photo of the bottom of the saddle shows that same zig zag pattern that you are suggesting.

It looks like they could have added a set of oil lines from the "One Shot" oiler system to the bottom ways but they didn't.

Just a personal observation but it looks like the current arrangement almost invites grinding swarf into those oil grooves and gives it a higher chance of swarf getting between the slides and causing premature wear.

I would rather replace the slides with a solid one piece strip and cut a zig zag groove into the new slides (without going all the way through as you pointed out), then just make it a point to manually give each pocket at the ends a little shot of way oil before each use.

I thought about adding some lines from the "One Shot" system but then I would have to worry about what size of orifice to use so they all get the right amount of oil distribution, for me it's easier just to add way oil manually before each use.

It appears that all of these slide materials are PTFE with various other anti-wear enhancing ingredients.

Teflon is just a brand name and generally refers to a straight PTFE material.

Rulon142 appears to have one side already prepped for the adhesive so I may go ahead with Rulon142 from the folks you posted a link to (Thanks for that).

I don't mind going through the ink printing and scraping process, I've done that many times in the past (only on bare iron though), it is a tedious and time consuming process but worth it in the end (BTW, I'm aware of your knowledge and experience with printing and scraping).

I've already printed the bottom of the saddle and it's in very good condition as is.

Anyway, thanks for your time and suggestions!!

Have a great day!!

Joe