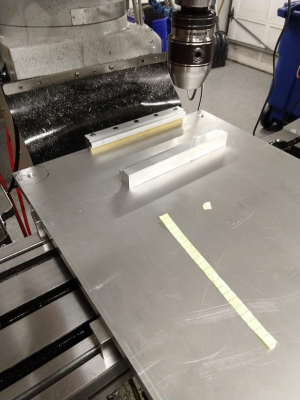

I have to pin (2 dowels) and tap for 3 1/4-20 SHCS. The piece (2) is 1" x 8" on a 16" x 18" plate. Both pieces are aluminum. I was able to get the first one as it was on the edge of the plate and clamping was no problem. The other piece is parallel to the first four inches away. I could maybe get one clamp on the end and then just one screw after that would be able to hold it in place.

My thought though was to glue it in place for the drilling and tapping. I tried Loctite super glue but never took hold.

Any suggestions for something that will bond aluminum to aluminum?

My thought though was to glue it in place for the drilling and tapping. I tried Loctite super glue but never took hold.

Any suggestions for something that will bond aluminum to aluminum?