- Joined

- Jan 20, 2018

- Messages

- 5,649

Maybe not doable with what you have, but for maximum accuracy, deep hole drilling is done with both part and drill rotating (in opposite directions of course). Perhaps on a lathe with a live spindle on QCTP and part held in 4-jaw chuck.

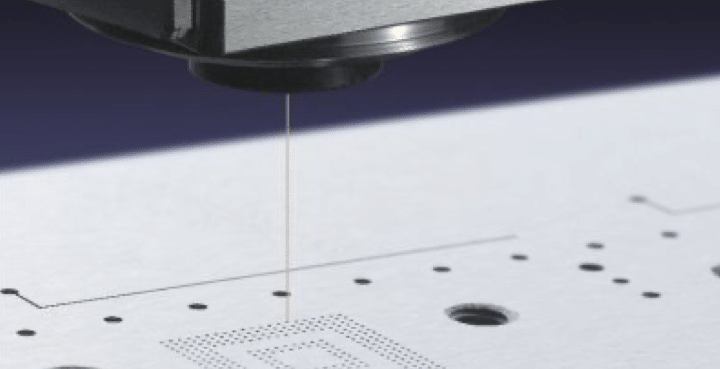

Deep Hole Drilling Process

Rotating Tool

Deep Hole Drilling Process

Rotating Tool

- Typically used for non-symmetrical components, or round parts with off-center holes

- Cutting speed is determined by tool spindle speed

- Drill drift can be significant when compared to rotating workpiece, or counter-rotating process

- Typically used for round parts with a deep, on-center hole

- Cutting speed is determined by part, balanced to allow high rotating speeds

- Drill drift is reduced compared to rotating tool only

- Ideal process for round parts with a deep, on-center hole

- Cutting speed is determined by a combination of tool and workpiece rotation

- Provides optimal hole straightness and concentricity

Last edited: