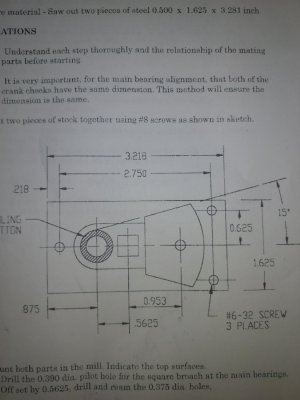

I wonder if some one would sell me a couple of pieces of mild steel and broach a 3/8 square hole in them. They are the crank cheeks for a 9 Cyl radial. the 2 pieces are bolted together and the hole broached so that they are in alignment. Attached is a pic of the dimensions. The steel parts are .500 x 1.625x 3.218. This is for a model 9 Cly radial.

Pls let me know if you can help and how much it will cost. I cant see spending almost $200.00 on a broach I will only use once.

Thank you

Ron

Pls let me know if you can help and how much it will cost. I cant see spending almost $200.00 on a broach I will only use once.

Thank you

Ron