- Joined

- May 27, 2016

- Messages

- 3,479

I have some chunks of nice steel, 31mm thick and 120mm x 60mm (about 1.2" thick and 4.7" x 2.3").

The 31mm apart faces are parallel to within a tenth thou, so they are sometimes handy as a sort of fat parallel, but the perimeters are not as in a rectangular block. They have the profile of whatever hydraulic pump kit they were originally destined for.

They don't rust - so not just some nearly tool steel.

They are magnetic, so mostly iron in there.

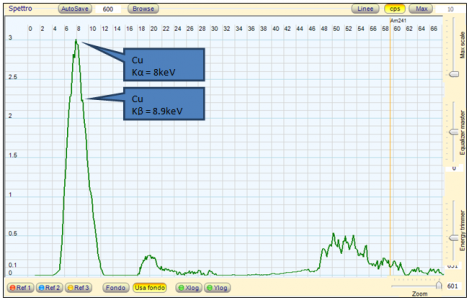

It seems there is not much between the "spark test" on a grinder, and some expensive kind of analysis.

I can't afford one of those FLIR things which are only cost-effective if they are identifying exotic stuff all all day long.

Trying for density once let me identify a nice chunk of titanium, but I did have some other clues.

Is there some lower cost way of figuring out what is in the alloy?

The 31mm apart faces are parallel to within a tenth thou, so they are sometimes handy as a sort of fat parallel, but the perimeters are not as in a rectangular block. They have the profile of whatever hydraulic pump kit they were originally destined for.

They don't rust - so not just some nearly tool steel.

They are magnetic, so mostly iron in there.

It seems there is not much between the "spark test" on a grinder, and some expensive kind of analysis.

I can't afford one of those FLIR things which are only cost-effective if they are identifying exotic stuff all all day long.

Trying for density once let me identify a nice chunk of titanium, but I did have some other clues.

Is there some lower cost way of figuring out what is in the alloy?