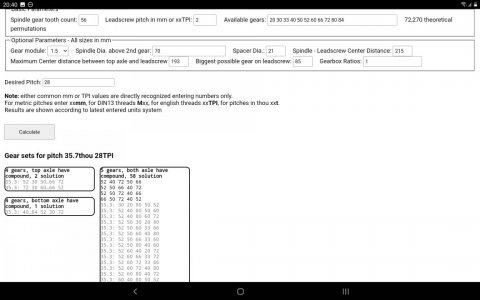

I put above a general formula to get the module of any (metric) gear that one can measure.Only thing I am unsure of is module. I assume from others it is 1.5.

In general, the bigger the gears, the larger the module. 1.5 is reasonable for ours, small one would use 1 or 1.25

I don't care about under which domain is hosted, it's in the public domain, and can be used on PC/mac/mobiles etc even without servers or the internet at all.you would just need to maintain your domain.

Last edited: