- Joined

- Aug 27, 2014

- Messages

- 65

Hi Everyone,

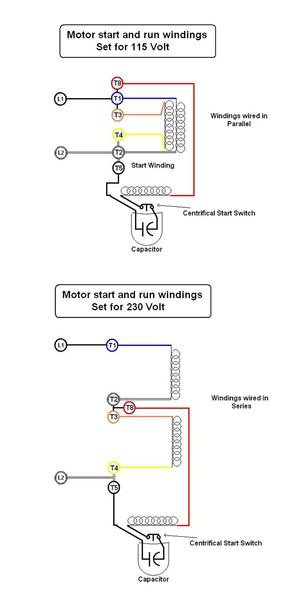

I am enjoying setting up and testing my new RF31. I am very happy with the rigidity and good cuts. But the big cast iron motor is too hot to touch.

Is this normal? I was not making heavy cuts, and not for an extended amount of time.

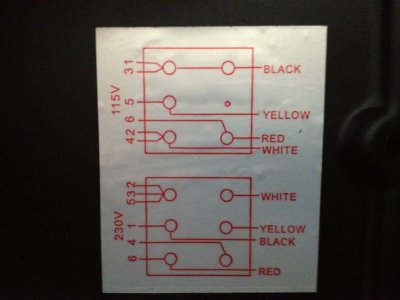

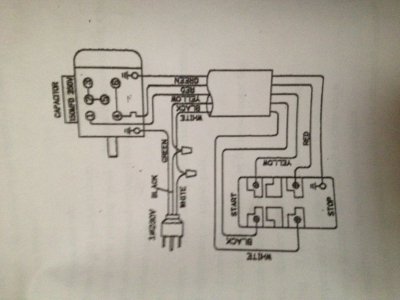

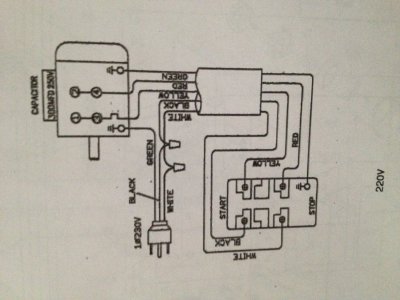

The mill/drill was supposedly delivered 230v, 1 phase; and it's plugged into the same outlet that my 230v, 1 phase lathe has been on for 20 years.

What do you guys think? I am not trained in electrical matters.

CannonFodder

I am enjoying setting up and testing my new RF31. I am very happy with the rigidity and good cuts. But the big cast iron motor is too hot to touch.

Is this normal? I was not making heavy cuts, and not for an extended amount of time.

The mill/drill was supposedly delivered 230v, 1 phase; and it's plugged into the same outlet that my 230v, 1 phase lathe has been on for 20 years.

What do you guys think? I am not trained in electrical matters.

CannonFodder