I feel quite different regarding the six inch vise. I have a jet jmd18 pfn. Table is slightly bigger but the head room is quite a bit more at it s highest point 26" inches spindle to table distance.

I feel the added mass is quite important for me. It really does smooth things out. I can open it up nine inches and put a smaller vise in it. Having the luxory of all the headroom allows me to keep the vise on the swivel base and have the vise mounted in the x plane and don t have to worry about room for tooling.

The vise does get restricted somewhat in y but if I had a smaller vise with such a small opening it would restrict me more than having nine inches to play with on opening plus I can stick it out the end close to the column. I do plan to make a cast plate offset to mount the vise to the table without the swivel will gain just about all of my y.

One thing you have to remember and why To choose the round column that gets put down by all the clueless that should never comment on a round column mill unless they have or had one is the fact you can mount the vise anywhere on the table and spin the head to do work you can t do on a solid column. Put the vise way out to one side sticking off the table and have acces with the ability because of the round column.

I think you are restricting yourself with a smaller vise. I presume you have a clamp kit. With the two you should be set.

With the six inch and a good toolmakers vise at three or four inches and with mounting in the six inch opens doors for you to move things around and get work done you may never have been able to. You may not see the possiilities now but experience will take care of that!

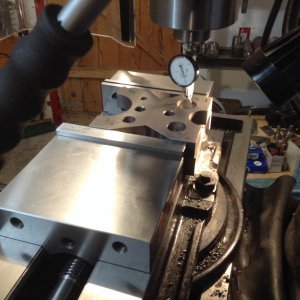

Here is a project I finished up some time ago. Cast press plates turned into a square/v block with radiuses and holes to press out bearings from shafts from 1/4" to 2.5". Here I am boring out the 1.25" hole. The cast pc. Are five inches long themselves.

I feel the added mass is quite important for me. It really does smooth things out. I can open it up nine inches and put a smaller vise in it. Having the luxory of all the headroom allows me to keep the vise on the swivel base and have the vise mounted in the x plane and don t have to worry about room for tooling.

The vise does get restricted somewhat in y but if I had a smaller vise with such a small opening it would restrict me more than having nine inches to play with on opening plus I can stick it out the end close to the column. I do plan to make a cast plate offset to mount the vise to the table without the swivel will gain just about all of my y.

One thing you have to remember and why To choose the round column that gets put down by all the clueless that should never comment on a round column mill unless they have or had one is the fact you can mount the vise anywhere on the table and spin the head to do work you can t do on a solid column. Put the vise way out to one side sticking off the table and have acces with the ability because of the round column.

I think you are restricting yourself with a smaller vise. I presume you have a clamp kit. With the two you should be set.

With the six inch and a good toolmakers vise at three or four inches and with mounting in the six inch opens doors for you to move things around and get work done you may never have been able to. You may not see the possiilities now but experience will take care of that!

Here is a project I finished up some time ago. Cast press plates turned into a square/v block with radiuses and holes to press out bearings from shafts from 1/4" to 2.5". Here I am boring out the 1.25" hole. The cast pc. Are five inches long themselves.