- Joined

- Dec 30, 2020

- Messages

- 10

..and total machine shop amateur

I was looking at PM based on other Youtube videos and research, including this forum. I received the mill last week and had time this weekend to unpack, setup and push a high speed turning thingy into a chunk of aluminum Man, I'm going to have a billion questions over the coming months and years. I've been watching hundreds of Youtube machining videos since around June to make sure I was still interested and I got hooked. And, to think, I ordered a PM-1440GT too.... my head is going to explode as much as my wallet already has.

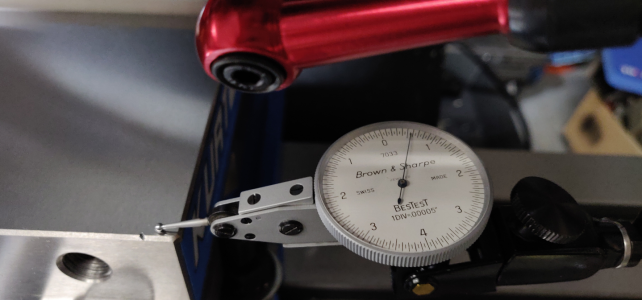

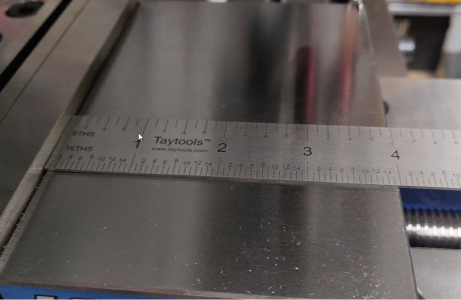

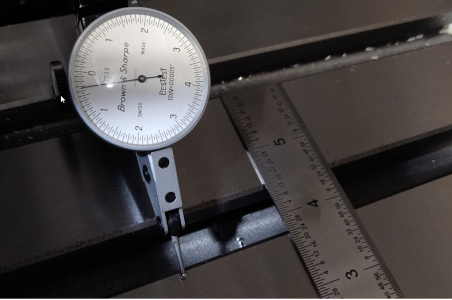

I've been looking to setup a metal shop for many years...about 20 or so... But, as you can imagine, life got in the way. I finally have a real mancave, so went to town buying equipment. I have no idea what I'm going to start first as far as a project. But, for now, decided to do the wax-on-wax-off basic exercises (i.e. "machine a bar of aluminum.... now make one thickness .500" exactly"). I ended up machining a bar of 7" with one side of the bar exactly .500" thick and far end .499 - not bad considering the awkward way I trammed mill (I didn't have an indicator holder to mount to the spindle - I'll do it correctly this weekend).

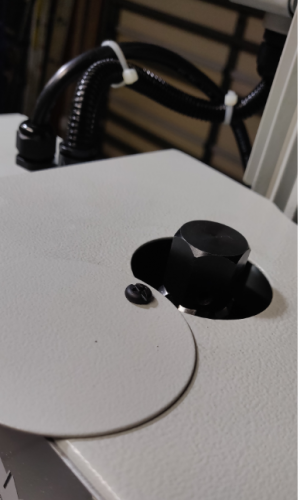

Anyway, back to the 833... My plan is to run it as a 100% manual mill for awhile and then convert it to CNC. or, maybe buy another model for CNC. Not sure right now. I had no issues purchasing the mill. The shipping was OK - they actually wheeled the boxes into my garage (the horror of it being dropped off at the end of my driveway was avoided. There was, however, some damage to the top of the crate holding the mill which I notated with the shipper and notified PM. Looks like the shipper dropped something extremely heavy onto the top of a precision instrument - I don't have much luck with shippers of big pieces.. They always seem to bugger something up. In my case (you can see from the pics), it only smashed the motor cover - the fan inside still spins without grinding and I didn't notice any issues using the mill. On the plus side, all the accessories were nicely packed in a separate box (I was a bit scared after seeing Clough42 video where they were bouncing around in the stand- lol).

Ok, now for the questions:

1) The hand wheels for X leadscrew- there's bolt on each. I loosely tightened them and of course, one spun almost completely off. When I tighten both down hard, it becomes extremely difficult to move. I'm not sure of the mechanics on what's happening. But, is there a rule of thumb here? tighten snug just before wheel resistance increases? One of the hand wheels has this annoying behavior where you need to push it in to turn the leadscrew. Seems like a "feature", but feels like a bug- Am I missing what the purpose of this is?

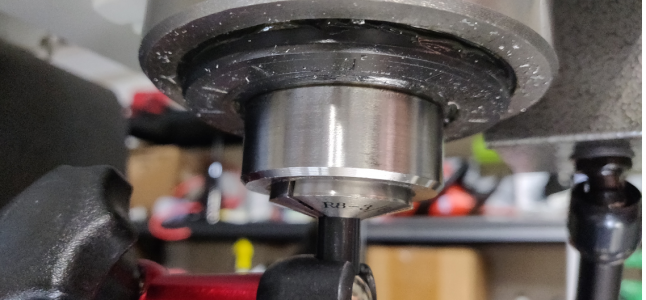

2) Drawbar - I never noticed until I started to use this, but in videos I've watched for other mills, its easily accessible. This thing is short and ends up buried in the machine to the point where I need to use a socket wrench instead of more convenient crescent style. Am I missing some attachment? From the manual, it seems to stick out several inches. Also, how in the world do you tighten it? The mills I've seen have a tool to hold the spindle while you use another took to tighten the drawbar. However, the spindle looks smooth and I don't see anywhere to attach a tool. Hand-holding it didn't really seem to get it tight enough - I had the end mill totally stop while making a .1 cut in aluminum.

I can't wait to get back in the cave, so much to learn.. This machine is nice and, from what my non-machinist eyes tell me, built real well. Can't wait for the lathe- I just don't know how I'm going to move the beast

I was looking at PM based on other Youtube videos and research, including this forum. I received the mill last week and had time this weekend to unpack, setup and push a high speed turning thingy into a chunk of aluminum Man, I'm going to have a billion questions over the coming months and years. I've been watching hundreds of Youtube machining videos since around June to make sure I was still interested and I got hooked. And, to think, I ordered a PM-1440GT too.... my head is going to explode as much as my wallet already has.

I've been looking to setup a metal shop for many years...about 20 or so... But, as you can imagine, life got in the way. I finally have a real mancave, so went to town buying equipment. I have no idea what I'm going to start first as far as a project. But, for now, decided to do the wax-on-wax-off basic exercises (i.e. "machine a bar of aluminum.... now make one thickness .500" exactly"). I ended up machining a bar of 7" with one side of the bar exactly .500" thick and far end .499 - not bad considering the awkward way I trammed mill (I didn't have an indicator holder to mount to the spindle - I'll do it correctly this weekend).

Anyway, back to the 833... My plan is to run it as a 100% manual mill for awhile and then convert it to CNC. or, maybe buy another model for CNC. Not sure right now. I had no issues purchasing the mill. The shipping was OK - they actually wheeled the boxes into my garage (the horror of it being dropped off at the end of my driveway was avoided. There was, however, some damage to the top of the crate holding the mill which I notated with the shipper and notified PM. Looks like the shipper dropped something extremely heavy onto the top of a precision instrument - I don't have much luck with shippers of big pieces.. They always seem to bugger something up. In my case (you can see from the pics), it only smashed the motor cover - the fan inside still spins without grinding and I didn't notice any issues using the mill. On the plus side, all the accessories were nicely packed in a separate box (I was a bit scared after seeing Clough42 video where they were bouncing around in the stand- lol).

Ok, now for the questions:

1) The hand wheels for X leadscrew- there's bolt on each. I loosely tightened them and of course, one spun almost completely off. When I tighten both down hard, it becomes extremely difficult to move. I'm not sure of the mechanics on what's happening. But, is there a rule of thumb here? tighten snug just before wheel resistance increases? One of the hand wheels has this annoying behavior where you need to push it in to turn the leadscrew. Seems like a "feature", but feels like a bug- Am I missing what the purpose of this is?

2) Drawbar - I never noticed until I started to use this, but in videos I've watched for other mills, its easily accessible. This thing is short and ends up buried in the machine to the point where I need to use a socket wrench instead of more convenient crescent style. Am I missing some attachment? From the manual, it seems to stick out several inches. Also, how in the world do you tighten it? The mills I've seen have a tool to hold the spindle while you use another took to tighten the drawbar. However, the spindle looks smooth and I don't see anywhere to attach a tool. Hand-holding it didn't really seem to get it tight enough - I had the end mill totally stop while making a .1 cut in aluminum.

I can't wait to get back in the cave, so much to learn.. This machine is nice and, from what my non-machinist eyes tell me, built real well. Can't wait for the lathe- I just don't know how I'm going to move the beast